This is a Veteran Owned site

|

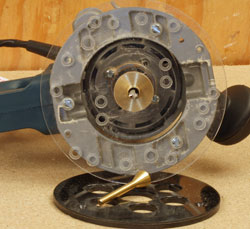

Installing an aftermarket baseplate with adjustment capability is easy and fixes a multitude of alignment errors. click image to enlarge |

Centering a Guide Collar On the Bit

Bringing accuracy to your soon to be less frustrating world

Text, photos and video by Tom Hintz

Posted - 6-5-2010

I constantly get emails from woodworkers who are having problems with dovetail and other router jigs, often very similar to the ones I use. However, they are not able to get the same results that I show. While a few are certain that I am doctoring the photos and/or video, the more Earth-based folks know there is a more logical cause for their issues. In many cases we find that a miss-alignment of the guide collar and bit are at the heart of the problem. If you are having problems with fit or accuracy when using a guide collar in your router read on....

Close Enough Isn't

For many router operations the factory baseplate works just fine. It may be a little off center but when using bearing guided bits or performing other freehand, non-guide collar operations there is little or no adverse effect. In this case, close enough can be just that - close enough.

|

|

With my old baseplate (left) the bit was off center. That miss-alignment caused an otherwise perfect setup (and Leigh dovetail jig) to leave gaps on the sides of some pin/tail joints. Click images to enlarge |

|

When using a guide collar in the baseplate, alignment problems between the bit and the guide collar can become painfully evident. It is important to note that the guide collars themselves are seldom the problem because of how they are fabricated. I have checked a bunch of them and have yet to find a measurable amount of error though I have not measured the really "el cheapo" versions.

If the bit is not centered within the guide collar the interaction between the guide collar and a jig is compromised and accuracy is something you wish for but won't get until you fix this. To make matters worse, if you rotate the router while making a guide-collar-controlled cut the bit actually swings through a small arc making things even worse. If the bit is off center within the guide collar on a dovetail jig it can force cutting too much from one side of a pin or tail and not enough from the other side. Rotate the router as you move across a dovetail jig and the errors on subsequent pins or tails could be reversed. The result can be unexplained gaps along the sides of some pins and/or tails in a joint that otherwise fits nicely or may even be too tight.

|

The Woodcraft base plate fits many routers, making it easy to get one for your shop. Click image to enlarge |

If you are very lucky, the factory baseplate can be turned or adjusted sufficiently to correct the error. Unfortunately, if you reside in the real world there is a much bigger chance that an aftermarket adjustable baseplate is the only effective option.

Tweaking the Factory Plate

Most baseplates are secured to the metal router base with three or four equally spaced screws. That means you have three or four positions in which it can be installed. If your stars are perfectly aligned (unlike your router), one of those mounting positions might be very close to perfect. This is where we actually hope that the center hole in the baseplate and the screw holes in the router base are sufficiently in error that they magically align when we hit on that one perfect mounting position. Oddly enough this actually works from time to time but not frequently enough to get your hopes up.

A few factory base plates have intentionally oversized mounting holes that can allow adjusting its position. In that case, you may be able to adjust out the alignment error. In most cases, the mounting holes are tapered which eliminates repositioning for correction. The holes in most baseplates that accept and position the guide collar are located (and sized) close enough that there is no meaningful alignment available there either.

Corrective Baseplate

|

|

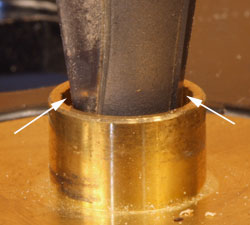

The Woodcraft plate came with flat-bottomed screw holes (left) and square-shouldered screws to fit the routers making installation very easy and fully adjustable. The kit also included the machined centering pin (right) that with the adjustment capability of the plate, make it possible to align the guide collar with the bit perfectly. Click images to enlarge |

|

My Bosch #1618 D-handled router has been my favorite for all of my precision routing needs, especially when using my Leigh D4R Dovetail Jig. The bad news is that when I installed a Porter Cable stepped-hole baseplate (Bosch includes screw holes in the base for it) the guide collar was miss aligned with the bits. I turned the PC baseplate to all three available positions and the alignment issue remained consistent. The only real way to fix this is with an aftermarket, adjustable baseplate.

I ordered an adapter baseplate from Woodcraft (Woodcraft #144931) which comes with mounting holes for a bunch of common routers, the necessary flat shoulder screws and an alignment pin with a tapered head. Precision routing in my shop was about to get a bunch more precise.

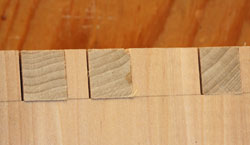

Before installing the adapter base plate I set up my Leigh D4R jig and cut a set of through dovetails. This piece turned out with the gaps around the pins and tails showing that the guide collar is not perfectly aligned with the bit.

Installation

|

After installing the Woodcraft Centering Base Plate I re-cut the joint using everything I did before except for the new baseplate. The difference was dramatic. I had minor chipping along a couple joint lines but that goes away with normal sanding. The alignment was perfect. Click image to enlarge |

Attaining centering nirvana is remarkably simple with the baseplate adapter. Remove the old baseplate and if not already there; install a 1/4" collet to accommodate the centering tool. Install the guide collar to be used in the adapter baseplate and tighten its locking ring firmly. The guide collar must have an ID that is a bit less than the diameter of the centering tool. I noticed that the hole for the guide collar is machined close enough that the flange of the guide collar literally snaps into place. Identify the correct hole pattern in the adapter base plate for your router, the compatible screws and install the base plate adapter but only snug the screws lightly for now. We want to be able to move the base plate for centering.

Install the centering tool and adjust its height so that the taper is in contact with the guide collar. Adjust the position of the base plate adapter so that the centering tool makes full contact with the guide collar all the way around and then tighten the base plate adapter mounting screws. Make sure that the centering tool is still in full contact all the way around on the guide collar and you are done. All that remains is remembering not to move the base plate adapter or to re-align it if you do. Just removing and re-installing the guide collar should not have an impact on the alignment though it is easy to check with the alignment tool just to be sure.

After installing the adapter baseplate I re-cut a set of through dovetails using the same Leigh D4R jig, the same setup, router, guide collar and bits. The only change was the adapter baseplate but the results were dramatic. Where there were large gaps along the sides of some pins and tails I now had clean fitting edges. The photos show the joints simply pressed together without any sanding or other finishing "work". The "after" edges still show minor chipping that will go away when the joint is sanded. Other than that, the fit is perfect and gap-free. Plus, I was able to snug the overall joint fit up a tad and still be able to press it together fully.

Conclusions

Video Tutor |

|

If you have been fighting ill-fitting dovetail or other joints that require the use of a guide collar it is time to check this alignment. I continually find people who are upset with dovetail jigs that really have an alignment issue between the guide collar and bit. The base plate adapter used in this story (Woodcraft #144931) has a normal street price of $26.99 but was on sale for $19.99 (9-12-2009) when I bought it. Remember that it includes multiple hole patterns (the page at the pricing link below has a list of compatible routers) and all of the screws needed for installation. It also comes with the centering tool.

This is an easy way to fix a very common centering problem that can frustrate you in many woodworking tasks. I keep my base plate adapter and related parts in a special place in my Rolling Jig Workstation where it is always close at hand because I have plenty of other things to frustrate me that can't be fixed so easily.

Have a comment on this story? - Email Me

Back to the Tips & Tricks List

All written, photographic and drawn materials are property of and copyright by NewWoodworker.com LLC 2000-2019. Materials may not be used in any way without the written permission of the owner.