This is a Veteran Owned site

Should I Buy A Jointer or Planer First?

Yes, there is a logical answer - besides buying both at once

Text & photos by Tom Hintz

Posted - 8-8-2008

|

|

Deciding which of these machine to buy first has perplexed woodworkers for ages. There is a simple answer though - besides buying both at once. Click imaged to enlarge. |

|

A frequent question from new and a surprising number of veteran woodworkers is whether to buy a jointer or planer first. Nearly all want both machines but trying to keep the budget in sight can mean one must come before the other. After reading many opposing views on this dilemma, some based on rather "unusual" justifications, I decided to give common sense a try to come up with an answer.

Right now the folks from the hand tool camp are yelling to buy hand planes. That certainly is an option if using hand tools is appealing to you. I am not a hand tool guy and am not proficient at using them so we won't go there in this article. However, it is important to remember that we can be good people (and real woodworkers) whether we enjoy using machines or hand tools or both.

Understanding the Basics

|

The jointer "sees" only one surface of the wood so has no idea if it is cutting that surface parallel to another or not. Most often, not. Click image to enlarge |

First, we need to understand what a joiner and planer can and cannot do. There are misconceptions about both machines that have confused this issue to a bunch of woodworkers, often in a big way.

Jointers straighten one surface of a piece of wood at a time. By using the fence we can make an adjoining surface square or intentionally bevel a corner. Because the jointer only works with one surface at a time, there is no way for it to make any surface truly parallel to another. This is an important point that can be difficult to get firmly locked in your mind. The jointer can make adjacent sides square (90-degrees) to each other yet not parallel. Think of a table leg that is tapered on two sides. All four sides can be square (90-degrees) to each other but the tapered surfaces are not parallel to the opposing surfaces.

This lack of parallelism is the result of the jointers single point of reference. A jointer tends to taper a board as the number of cuts increases. There does not have to be anything wrong with the jointer or its set up for it to taper the wood. Tapering can originate in where material must be removed to begin correcting the defect. Bad technique can accelerate the tapering but mostly it is a simple function of the machine working with one surface at a time. This is why the jointer often is used to get one surface flat before we take the wood to the planer. When straightening the edge, we usually straighten one edge on the jointer and then go to the table saw to cut the other edge parallel to the jointed one. You can go back to the jointer to make one final (just one and light) pass to clean up the sawn edge when necessary.

|

Because the planer "registers" the wood on the table surface, the knives cut the opposing surface parallel to it. The jointer has no way of doing this. Click image to enlarge |

The planer works off of two opposing sides of the wood. The surface straightened on the jointer is placed on the planer table and then the planer cutters work on the opposite surface. Because the cutters are parallel to the table surface, they machine the opposing surface of the wood parallel to the surface facing down onto the table.

It is important to remember that if the surface of the wood on the table is not perfectly straight, the planer will accurately replicate the defect on the upper surface. That is because the planer only "sees" a short section of the board directly under the cutters. If the board has a bow over its length, the planer will not remove it. The opposing surfaces will be parallel to each other but nearly all of the bow will remain.

The planer also makes the thickness of the wood consistent. This is why the planer is most often used to reduce the thickness of the wood. It does a better job of it than the jointer and keeps the wide surfaces of the board perfectly parallel to each other at the same time.

Which Comes First?

I kept track of how many times I used my jointer and planer for almost a year. Several regular viewers of NewWoodworker.com also kept track of their jointer/planer usage to provide a more balanced picture. The results were very clear - get a jointer first.

There are more uses for a jointer overall but one, straightening edges for glue ups, really tipped the usage numbers in its favor. This may be due to the fact that a large number of relatively new woodworkers buy dimensioned lumber. Regardless of how nicely the wide faces are finished, this dimensioned wood still needs to be jointed to get perfectly straight edges that make solid glue joints possible.

Working Together

|

|

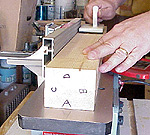

If we make a surface flat on the jointer (left) and then put that surface on the table of the planer (right), the result will be flat, parallel surfaces. Use the jointers fence to cut an adjoining surface square to the first surface and the planer can make the piece truly straight and square. Click images to enlarge |

|

Having a jointer and planer in the shop lets you produce very accurate wood for your projects. Freshly straightened wood with a consistent thickness makes it far easier to create clean, tight-fitting joinery. It is also much easier to build square projects when the wood itself is straight and consistent in thickness.

Having both machines also allows using rough sawn wood. While there is a cost savings in rough sawn over already milled wood, the important thing is that you get to decide what the final dimensions. Plus, you can be sure that the dimensions of all of the wood used in a project are identical. In many locations there is often a much wider variety of species of wood available in rough sawn form.

Conclusions

For most woodworkers, getting the jointer first is the best plan. The fact that nearly all woodworkers use their jointers so frequently to prepare edges for glue ups seals the deal on this point. However, there is also a safety factor in getting the jointer first. Trying to make rip or even cross cuts when the edges of a board are not perfectly straight can be dangerous. Without a straight edge to run along the fence or hold against the miter gauge, the wood can rock during the cut, substantially increasing the chances of having a kickback.

Buying the jointer and planer at the same time is the best idea if the budget will survive. If you are in the more common financial bracket that dictates getting one machine at a time, get the jointer first and then immediately start whining about needing a planer.

See our special Jointer Basics How-To DVD! - Click Here

Have a comment on this story? - Email Me

All written, photographic and drawn materials are property of and copyright by NewWoodworker.com LLC 2000-2019. Materials may not be used in any way without the written permission of the owner.