This is a Veteran Owned site

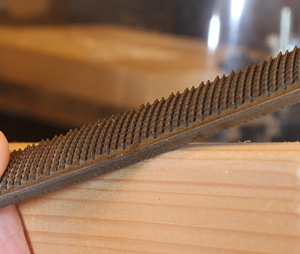

The Lowly RaspThe one hand tool I depend on – ShhhhhText, photos and video by Tom Hintz Updated - 1-20-2013 If you are like me, tools that don’t plug into an electrical socket can foster pangs of inadequacy, or that you accidentally threw yourself back in time to the pre-electricity days. But even I can occasionally use and even like using one of the purest hand tools there is. I know that scares some of my regulars but in this case, get over it. The wood rasp, no matter how archaic it appears remains a very useful tool in modern woodworking shops and should always be close at hand. The BasicsRasps come in a wide variety of shapes and sizes. Some have wooden or plastic handles and others no handle at all. The rasp shown here is one of the most basic but is actually four rasps in one. It has fine and coarse (in rasp standards) versions of flat and round shapes. This variety of surfaces makes the rasp remarkably useful in any woodworking shop. Rasps are made out of hardened metal much like their metal file counterparts but the coarse nature of the pattern on the rasp helps it remove material quickly yet resist buildup like you can get with a file. I have had my rasp load up just a few times on soft or wet wood but cleaned the surfaces instantly with a wire brush. If you wear out a rasp, even a cheap one like the version I use you are doing some extraordinary woodworking!

In the ShopRasps are in many respects very rough files, designed for use on wood. While the rasp surfaces can look very aggressive the surface they are capable of producing is surprisingly smooth. With the rasp shown here the rough surfaces are capable of fast removal of material but leaves a relatively rough-feeling surface. However, turn it around to one of the finer surfaces and you can quickly smooth that surface out to where it comes right in with a sander in a very short time. I’d like to say I know how it does that but I am not sure. I think that also speaks to how well thought out the rasp is these days. I also like to use my rasp to fit tongue and groove or mortise and tenon joints. Knocking a little off the face of a tongue or tenon is easy and quick with the fine side of the rasp. The rasp is also way faster and safer than trying to set up the table saw to correct a minor fit problem on a joint. Rounding a corner, small or large can be done quickly with a rasp and then finish sanded for finish quickly. The rasp can also be a workable solution when tools like routers can’t reach an area. I think that if we can overlook the pure simplicity of the rasp we just might realize how valuable this little tool is in our shops. I have seen estimations that the rasp was conceived around the time King Arthur's Knights were whacking each other with hand-forged swords. While I am sure that the metals and manufacturing processes behind todays’ rasps have advanced it is just as obvious that the concept behind the rasp has remained largely unchanged for a very long time. If you don’t have a rasp in your shop, you need to get one. They can be had for between $10 and $15 for the four-surface version I have (very popular by the way) so this is not a bank-breaking experiment for any budget. I think that with a little in-shop experience you will learn to appreciate this little hand tool. And if you are known as a power-tool-only person you can just close the shop door when using the rasp – as I do.

Have a comment on this story? –Email Me! Back to the Tips & Tricks List

|

||||||||

All written, photographic and drawn materials are property of and copyright by NewWoodworker.com LLC 2000-2019. Materials may not be used in any way without the written permission of the owner.