This is a Veteran Owned site

|

The Carter AccuRight(tm) Circle Cutter is easy to install and use plus brings the typical Carter quality. Click image to enlarge |

Carter AccuRight(tm) Circle Cutter

An accurate, tough and easy-to-use jig

Text, photos and video by Tom Hintz

Posted - 12-1-2009

Just when you thought that Carter had come up with everything you could hop up a bandsaw with they release another one! The Carter AccuRight(tm) Circle Cutter is simple to install and use yet very accurate and tough all at the same time.

If you have used Carter products in the past the quality of the materials and manufacturing will not be a surprise. Because few woodworkers have a dedicated circle cutting bandsaw the ease with which the Carter AccuRight(tm) Circle Cutter can be installed and removed is important to nearly all of us. And, it does both very easily and quickly.

The wood turns on a simple tapered pin that does not require a deep hole to be drilled in the stock. Also, all of the adjustment screws are top-mounted and countersunk into the cross bar so you always have a smooth surface on which the wood can turn during the cuts.

Installation

|

|

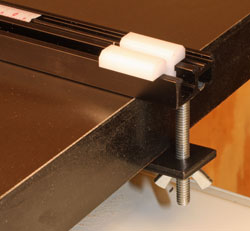

Fast, easy to use wing nuts make installation or removal simple. Note the white sliding supports (right) that help keep the wood level during the cut. Click images to enlarge |

|

Note: The Carter AccuRight(tm) Circle Cutter is fully compatible with the Carter MAGFENCE(tm) without having to remove or modify it. If you don't have the Carter MAGFENCE(tm), installation is equally easy. And it works with any blade width or design.

The Carter AccuRight(tm) Circle Cutter Jig installs using a pair of clamp arms, tightened with finger-operated wing nuts that secure it to your unmodified bandsaw table. The bolt and arm for the rear of the bandsaw table are pre-installed in the long track. The front (right from the operator's view) bolt and arm are installed in the T-slot and located along the track as needed for your table size. Tighten one nut to lock the bolt in place and then snug the clamping arms with the wing nuts.

Aligning the Carter AccuRight(tm) Circle Cutter is also fast and easy. Simply move the assembly across the table so that the tapered pin on which the wood turns is aligned with the teeth of the blade (not the center of the blade! It cuts at the teeth, not the center!) and make sure that the crossbar is square to the miter slot before tightening the guide track down to lock the jig in place.

|

|

The crossbar slides on the main rail (left) to set the cutting diameter. A magnified lens (right) makes setting the exact diameter wanted a no-brainer. This is a very fast and simple system that is also very accurate. Click images to enlarge |

|

Adjust the scale tape so that "0" is even with the blade and the installation is complete. Note that on bigger saws the tape might protrude out of the track some. On my 18" JET bandsaw the table is quite large so the 0 position is cheated a little farther down the guide track. A somewhat illogical reality about larger bandsaws is that their often-larger tables can actually limit the maximum diameter circle that can be cut with jigs. The blade is located farther down the guide track than it would be on a typical 14" machine table. On my big 18" I can still comfortably cut up to a 57"-diameter circle!

Setting Up the Cut

To set the Carter AccuRight(tm) Circle Cutter for the circle you want to cut you only need to move the crossbar down the main track until the magnified cursor is over the number representing half of the diameter you want. Then lock the crossbar in place with the hex head screws. That really is all there is to it.

When cutting larger circles where the Carter AccuRight(tm) Circle Cutter crossbar is off of the table adding a work support stand to keep the crossbar steady under the weight of the workpiece is all that is needed. Finally, move the included plastic supports so that they keep the stock size being cut flat during the operation and you are ready to go.

Sliding Pin

|

This sliding pin allows you to start the cut at the edge of oversized stock, slide the pin and wood back to its "home" position and turn the wood to make a perfectly round piece without flat spots around the edge! Click image to enlarge |

One of the more difficult things about using traditional circle jigs was getting the cut started. You could do it by accurately placing the pilot hole so that the cut actually began exactly at the edge of an accurately sized blank. The Carter AccuRight(tm) Circle Cutter has an ingenious cure.

A sliding locator pin lets you use an oversized blank, incurring a fully round piece after the cut. The pin slides away from the blade in a track in the cross bar. It moves enough to let you place an oversized workpiece on the pin and then slide it back into the blade to start the cut. When the pin returns to its "home" position a magnet locks it in place and you turn the blank normally to cut a perfect circle with no flat spots!

This is a remarkably simple fix that is very easy to use. At first I was concerned about the magnet releasing unexpectedly and allowing the blank to slide back away from the blade but that just does not happen.

To prep the wood you only have to make a pilot hole at the center of the blank that accepts the tapered pin on the Carter AccuRight(tm) Circle Cutter. Then just be sure to put that pilot hole over the locating pin.

After that all that remains is turning the stock slowly and letting the bandsaw do its job. The Carter AccuRight(tm) Circle Cutter insures that you get a perfectly round piece that is the diameter you wanted.

Video Tour |

In the Shop

Setting the Carter AccuRight(tm) Circle Cutter up and getting it ready for use is fast and easy. I had it out of the box and ready to cut wood in less than half an hour, which included time for taking photos. It really is that easy.

Between the broad crossbar and the repositionable supports, the Carter AccuRight(tm) Circle Cutter makes cutting perfect circles a virtually effortless, simple task. I also like the fact that it is installed with wing nuts. That means that the Carter AccuRight(tm) Circle Cutter can be removed just as easily as it is installed to keep your bandsaw free for other tasks. The Carter AccuRight Circle Cutter itself is easily stored in the shop.

Conclusions

The Carter AccuRight(tm) Circle Cutter is typical Carter in the quality of the design, materials and manufacturing. These guys just know how to do it right when it comes to anything related to a bandsaw. If you ever need to cut circles, having the Carter AccuRight(tm) Circle Cutter in your shop will make that task simple and fast. With a street price of just $49.99 (12-1-2009) this is a very reasonable investment that will last for many years to come.

Click Here to visit the Carter Products website.

Have a comment on this Review? - Email Me!

All written, photographic and drawn materials are property of and copyright by NewWoodworker.com LLC 2000-2019. Materials may not be used in any way without the written permission of the owner.