This is a Veteran Owned site

|

Despite its space-saving fold-up configuration, open it up and the JET 10" Job Site Saw is surprisingly capable. Click image to enlarge |

JET 10" Job Site Table Saw

Portable, compact and useful

Text, photos and video by Tom Hintz

Posted – 9-17-2010

While your shop space might be smaller than you’d like your table saw needs remain as big as ever. Finding a portable, space-saving table saw that actually performs has been a chore but now JET has an alternative in their 10" Job Site Table Saw. (JBTS-10MJS) While probably conceived as a job site machine JET did not forget the hordes of space challenged woodworkers. The JET 10" Job Site Table Saw appears capable of handling the job site or home shop with ease.

The Basics

The JET 10" Job Site Table Saw may have a small footprint but it boasts many full-sized features, starting with a back-friendly table height of 35”when the fold-up stand is open. Treaded 8”-tall tires on the stand make moving this 105-lb of saw to the workspace a markedly low-strain event!

|

|

The rear (left) and right side (right) table extensions/supports give you bigger saw capability without sacrificing accuracy or safety. Click images to enlarge |

|

The 30-1/4”-long by 21"-wide table size rivals many contractor saws and makes it possible to work with larger pieces of wood. Add outboard work supports and you can safely work with even larger pieces of wood. The JET 10" Job Site Table Saw is equipped with a pull-out rear support for better accuracy and safety. The JET 10" Job Site Table Saw has impressive capacities of 25” rip cuts to the right of the blade thanks to the pull-out right side extension. Cut depths also look like some cabinet saws with 2-1/2”-deep cuts at 45-degrees and 3-1/16”-deep cuts at 90-degrees! The 5/8”-diameter arbor is designed to accommodate 6”-diameter stacked dado sets at widths up to 13/16”!

The JET 10" Job Site Table Saw is powered by a 15A, 4.4-HP, 120V motor that develops 4000 RPM (no load) of blade speed. JET also includes soft-start technology in this motor to soften the start-up kick.

Blade and Guards

|

|

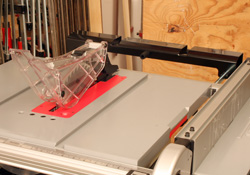

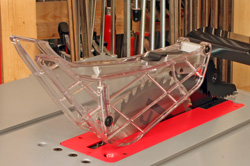

The motor and blade-surrounding shroud (left) are both mounted to the trunion so all move together. The blade guard system (right) is modular so it can be reconfigured to work as a riving knife. Click images to enlarge |

|

Changing the 10”-diameter blade on the JET 10" Job Site Table Saw is quick thanks to a pushbutton arbor lock and the included blade wrench. The standard throat plate is easy to remove, has leveling screws and provides plenty of room surrounding the blade area. JET includes a carbide-tipped blade with the JET 10" Job Site Table Saw so you can get up and running right out of the box.

The JET 10" Job Site Table Saw comes with an adjustable riving knife that can support the modular blade guard system or be lowered to work as a true riving knife, slightly below the height of the blade for groove type cuts. JET made the entire blade guard system modular and tool free so you have no excuse not to use it.

On the Fence

|

The T-square style rip fence is easy to use and very rigid for this kind of saw. Click image to enlarge |

The JET 10" Job Site Table Saw comes with a T-square style fence that is easy to move and lock down. This fence rides smoothly on cleanly made extruded aluminum rails that insure accuracy. The front guide rail features an easy to read rip scale. The fence head has a fine line cursor that makes setting very specific blade-to-fence distances simple. Of course, the cursor is adjustable so you can dial it in perfectly if that need arises.

JET also includes a full function miter gauge. This gauge has a T-shaped bar that keeps it accurate and also fits the special storage on the side of the JET 10" Job Site Table Saw when it is not in use.

Dust Control

Dust collection on the JET 10" Job Site Table Saw features a shroud that encloses most of the blade below the table. The shroud terminates in a 2-1/2”-diameter port at the rear of the saw. This port is compatible with most full-sized dust collectors or it can be easily adapted s needed. The shroud and dust port move with the blade so it remains effective regardless of the type of cut being made.

Transport Stand

|

|

With the stand open (right) the saw is comfortable to work on. Collapse the stand (right) and it is easy to save a bunch of floor space when it is not in use! Click images to enlarge |

|

The all tubular steel stand serves two purposes. It makes the JET 10" Job Site Table Saw mobile for job site use but also shrinks the footprint of this machine when it is in the stowed configuration. The large tires make it easy to move this saw over uneven ground or grass. It also has an adjustable foot that lets you dial out rocking on less than flat surfaces. In the stowed position the JET 10" Job Site Table Saw is much easier to store in a confined area. It does not disappear altogether but much of its footprint does.

The JET 10" Job Site Table Saw stand is operated with a single handle. Pull the handle and you can raise or lower the JET 10" Job Site Table Saw. The stand has a flip-lock to secure the saw when in the stowed position for transport. Whether you are opening it for use or lowering it for storage, the transition is fast and easy.

In the Shop

The JET 10" Job Site Table Saw came mostly assembled so my primary chore was putting it on the stand, an operation that took just minutes to complete. I went through the adjustments just to be sure but the JET 10" Job Site Table Saw came out of the box closely aligned. I tweaked the fence just a bit and was ready to cut wood.

The stand is easy to operate, locks solidly in the up position and the adjustable foot makes it easy to stop rocking of the saw on uneven surfaces. The large wheels roll easily over grass or uneven ground. In the stowed configuration the JET 10" Job Site Table Saw really does need remarkably small footprint for storage.

The JET 10" Job Site Table Saw seems to have more than adequate power. It certainly is not a cabinet saw in disguise but with a decent blade and moderate feed rate, it does just fine. I could bog the blade slightly when cutting 1-1/2”-thick oak but the same thing happens on contractor and 110V cabinet saws. Slow the feed rate a bit and blade speed variation goes away.

The fence system is accurate and seems to stay adjusted even after removing and replacing it a number of times. The square shape and pre-drilled through holes make attaching sacrificial faces or shop-made jigs easier and secure.

Video Tour |

Overall the JET 10" Job Site Table Saw did a good job throughout the evaluation. The table surfaces are flat and the stand solid when set up. Folding the stand for storage is a real space saver, something many of today’s woodworkers need.

Conclusion

The JET 10" Job Site Table Saw is a well-made, well-designed saw for this class of machine. Its features rival more expensive models which puts you dollars ahead by owning one. Better yet is that the JET 10" Job Site Table Saw performs better than I expected for a job site saw. The expandable work surface is really handy and lets you adapt to the space you have to work in.

With a street price of $599.99 (9-16-2010) you can save money while you save space. Better yet is that you don’t have to give up performance. This is a work site saw but its power and features make it think that it is bigger than it is. When you need a compact table saw that is a good thing!

Visit the JET Tools web site – Click Here

Have a comment on this review? –Email Me!

All written, photographic and drawn materials are property of and copyright by NewWoodworker.com LLC 2000-2019. Materials may not be used in any way without the written permission of the owner.