This is a Veteran Owned site

|

|

This JET 14" Band Saw (left) comes from the box with the most sought after accessories - including the riser block - literally built in! This saw also placed second in our annual Top Ten Tools of 2010! Click images to enlarge |

|

JET JWBS-14DXPRO Band Saw

Finally! No more riser block!

Text, photos and video by Tom Hintz

Posted - 6-29-2010

From whenever woodworkers started using band saws they also began using riser blocks to get more resaw capacity. This upgrade has been so common that a favorite sales enticement for many band saw manufacturers was offering the riser block as a bonus. JET finally just added the riser block height to the frame on their JET JWBS-14DXPRO Band Saw. Presto! A 14" band saw that comes out of the box the way most of us wanted it all along.

It's In the Frame

The JET JWBS-14DXPRO Band Saw has a heavy duty cast iron frame that now includes the additional height to offer a full 12" of resaw capacity. A problem has been that the riser block was usually wider than the frame itself to withstand the extra leverage of the taller assembly. On some other saw brands the wider riser block actually reduced the blade to frame capacity by 1/2" to 1" or so. JET had to increase the size of the frame to accommodate the increased height but they did that on the outside edge of the JWBS-14DXPRO Band Saw frame. That way they get the desired resaw height while retaining a full 13-1/2" cutting width. And you thought the manufacturers were not listening to us.

|

|

The tough 1-1/4HP motor (left) packs plenty of power for even the big, tough jobs. The two-speed, serpentine belt drive (right) transfers that power efficiently and smoothly. Click images to enlarge |

|

Building the former riser block into the frame does more than just eliminate buying a nearly mandatory accessory. Installing the riser block was not one of the more enjoyable chores in a woodworking shop. The frame of the JET JWBS-14DXPRO Band Saw also rids us of the sometimes frustrating process of getting the top and bottom wheels into alignment after the riser block was installed.

With the frame lengthened at the factory we also get away from having to add extension cords to the motor and/or switch, moving the switch, plus installing the blade guard and post upgrades. You just take the JET JWBS-14DXPRO Band Saw out of it shipping boxes, secure it atop the enclosed stand and you nearly are ready to go to work. For additional stability during large resaw operations an optional pair of steel "feet" that extend from the rear of the base cabinet are included.

Power and Speeds

The JET JWBS-14DXPRO Band Saw is equipped with a 1.25HP, 1PH 115/230V TEFC (totally enclosed fan cooled) motor that provides all of the power needed for the tough jobs. A nice design feature is that the motor is mounted on the lower saw frame rather than in the base cabinet. That makes adjusting the belt tension and changing speeds far easier. Keeping the motor up on the saw also frees up real storage space in the 17-1/4" wide by 15"-deep by 25"-tall base cabinet! The only down side is that the saw itself weighs right at 200 LBS so count on having a friend present to get it mounted atop the base.

The motor sends its power to the blade wheels through a serpentine belt that is known for quiet, slip-free operation. Its low profile also allows it to run cooler which reduces wear and helps prevent over heating of the belt and nearby bearings.

|

|

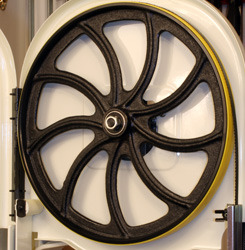

Precisely made,. machined and balanced cast iron wheels (left) run smooth and true on sealed ball bearings. Note the yellow polyurethane tires (right) that make seeing blade tracking easy, including through the upper cabinet window. Click images to enlarge |

|

The belt rides on a two step pulley at the lower blade wheel that lets you choose between two blade speeds. For most work you can use the 3000-FPM (feet per minute) or for the tough jobs and resawing you can slow the blade to 1500 FPM. And with the motor mounted on the saw frame, you do all of that in the lower wheel cabinet where you can actually see and reach everything!

Precision Wheels

The JET JWBS-14DXPRO Band Saw uses a pair of precision cast iron wheels that have been machined and balanced to eliminate vibration. Both wheels are fitted with high-quality polyurethane tires that run longer while retaining their critical shape.

The tires are colored yellow so you can clearly see the blade tracking. To make adjusting tracking even easier the JET JWBS-14DXPRO Band Saw has a "window" in the upper cabinet so you can visualize your tracking adjustments without leaving the cabinets open.

Both the upper and lower wheels run on sealed ball bearings. The oversize bearings help keep the wheels tracking straight while reducing power-robbing friction in the process. They also help keep the JET JWBS-14DXPRO Band Saw running smoothly and quietly.

Blade Tension and Relaxing

|

|

The blade tension release mechanism (left) is easy and fast to access and use. The cast iron table (right) gives you the room for working with big jobs, including bevel cuts! Click images to enlarge |

|

The JET JWBS-14DXPRO Band Saw uses a familiar hand operated screw and spring system to apply tension to the blade. The tension scale cast into the tension mechanism on the rear of the upper cabinet allows you to set the appropriate tension or make specific changes as needed.

JET also adds a single lever that relaxes blade tension when pulled down. Flip this lever up and the saw is ready for use again. Not long ago this was an extra cost option on band saws and standard equipment or not, should be used all of the time!

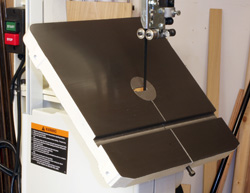

Large Table

A large, 15" by 15" cast iron table provides lots of surface to support big workpieces. The surface is finely ground to be sure it is flat and to keep the wood sliding smoothly during the cut. The table tilts up to 45-degrees to the front and 10-degrees to the rear. A handy bevel scale is included at the operator's side table locking knob under the table. The table has a miter slot machined in and is drilled for installation of an optional fence available as an accessory.

The table is split for blade access and has a tapered slip-in pin to maintain alignment of the table surfaces during operation. At the center is a round aluminum insert that supports the wood around the blade and focuses dust extraction at the immediate blade area when connected to a suitable dust collection machine.

|

|

This machine uses full ball-bearing guides (left) above and below the table. Most adjustments are easily made without tools! The guide post assembly (right) is very smooth operating and has a nice guard that is self-adjusting for the amount of post that is exposed. Click images to enlarge |

|

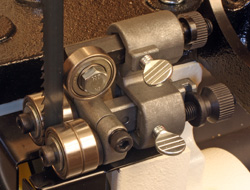

Roller Guides and Post

The JET JWBS-14DXPRO Band Saw features upper and lower roller bearing guides. These bearing guides use oversized, sealed ball bearings for very good control, smooth performance and long life.

All of the guides are easy to adjust with most having finger operated dial-type controls. The side guide roller bearings are mounted on eccentrics that when turned with a hex wrench makes getting the right clearance very easy.

The upper post is very rigid even when fully extended. JET also provides a very nice rack and pinion system for positioning the post for the stock being cut. This post system is operated by a knob on the front of the JET JWBS-14DXPRO Band Saw and is remarkably smooth. It also stays where you put it if you use the locking knob on the back of the upper cabinet.

The post has a full-length scale that lets the operator set the height very quickly for the size wood being cut. An auto-extending guard keeps the blade covered regardless of the post height. When raised all of the way the guard collapses onto itself and stays out of the way.

Dust Collection

|

|

a cast-in, 4"-diameter dust port (left) is located directly on the blade path beneath the table where it can be most effective. Jet also installs a brush on the lower wheel (right) that further enhances dust collection. Click images to enlarge |

|

The JET JWBS-14DXPRO Band Saw has a 4"-diameter dust port cast into the lower iron case. This port is located on the blade path just below the table where it can do the most good. When connected to a dust collector much of the dust that used to accumulate in the cabinets is taken away as it is created.

JET also installs a brush on the up side of the lower wheel. This knocks off most of the dust that sticks to the tire so it can be evacuated through the large port. There will still be some dust found in the cabinets but the quantity is far less than with the older dust collection schemes that appeared to be an afterthought, more so that the manufacturer could say it had one.

In the Shop

The JET JWBS-14DXPRO Band Saw comes in two large boxes - one containing the base cabinet and the other the saw itself. Both are nearly complete as they emerge from the boxes. Getting the saw itself on top of the base cabinet is definitely a two person job because of its 200-lb heft. Or as I did, me and my trusty hydraulic hoist. Bolt the saw in place on the cabinet and all that remains is to install the cast iron table. The fit and finish of the JET JWBS-14DXPRO Band Saw were first rate right out of the box. No scratches, rust or dents to be found anywhere.

|

|

Blade tension and tracking adjustments (left) are familiar and work well. the spacious base cabinet (right) has lots of useable space thanks to the saw-mounted motor. Click images to enlarge |

|

Because the motor is mounted on the saw rather than in the base cabinet, setup goes very quickly. I went over the guide bearing settings, check the belt tension (it was fine) and adjusted the table stop so that its surface was 90-degrees to the blade. I also checked the blade tension and tracking, both of which were correct (from the factory) for the general purpose 3/8" -wide blade that, came with the saw. I plugged the JET JWBS-14DXPRO Band Saw in and started it just to be sure everything worked and found that it hummed along nicely.

The JET JWBS-14DXPRO Band Saw appears big for a 14" band saw but remember that the frame is a good 6"-taller than standard 14" saws in this class that come without a riser block installed. The base cabinet is reasonably tall as well but that is a good thing considering the large amount of useable storage space within. In use, the JET JWBS-14DXPRO Band Saw heights - table surface and controls - are at comfortable heights.

During this evaluation I made a variety of straight and curved cuts with the JET JWBS-14DXPRO Band Saw and it handled all effortlessly. The roller guides are very effective in keeping the blade tracking properly which enhances accuracy and predictability of the cut. The motor has plenty of power for all cuts I could think of, including resawing some 11"+-wide poplar (1500-FPM) with the included general purpose blade. Maintain a moderate feed rate to let the blade do its work and the JET JWBS-14DXPRO Band Saw handles the chore easily.

The JET JWBS-14DXPRO Band Saw handled all of the common woodworking tasks I could think of easily and accurately. Despite being factory wired for 115V the JET JWBS-14DXPRO Band Saw cruised through all of the cuts and materials I could find in my shop. It just works very well in all respects.

Conclusions

Video Tour! |

The Carter Magfence used in this video is not supplied with the saw. Click Here to see my review of the Magfence. |

The physical size of the JET JWBS-14DXPRO Band Saw and its cutting capacities in both flat and resaw modes makes it a good fit for any size shop. It has plenty of power and all of the features woodworkers want most yet it carries a street price of just $899.99 (6-27-2010) that makes it high on the "bang for the buck" scale.

If you want a band saw that delivers the power and capacity to handle your shop needs, take a long look at the JET JWBS-14DXPRO Band Saw. JET tools have long been favorites of woodworkers because of their reliability and performance. Those traditions continue at JET and that makes the JET JWBS-14DXPRO Band Saw a good choice now and in the years to come.

Visit the JET Tools web site - Click Here

Have a comment on this review? - Email Me

All written, photographic and drawn materials are property of and copyright by NewWoodworker.com LLC 2000-2019. Materials may not be used in any way without the written permission of the owner.