This is a Veteran Owned site

|

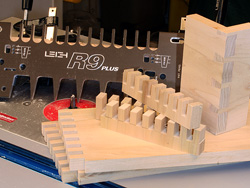

This is a very well made, economical jig for making perfect through dovetails and box joints of virtually any length! Click images to enlarge |

Leigh R9 PLUS Joinery System

Perfect dovetail and finger joints from a bargain-priced jig

Text, photos and video by Tom Hintz

Posted – 11-17-2011

Leigh Jigs (Canada) has become synonymous with quality joinery jigs for good reason. To many woodworkers – including myself – Leigh is simply the best that there is. Over the years Leigh brought other top-shelf jigs to the market but their dovetails jigs are recognized as the standard by which the others were measured. If there was a vacancy in the Leigh product line it was a low-cost dovetail jig. I say was because Leigh can hang the No Vacancy sign out front because that slot has been filled. And as the Leigh faithful knows Leigh wouldn’t add a product to its lineup if it didn’t work – or live up to their tradition of quality. The Leigh R9 PLUS Joinery System reviewed here fills that void with all of the quality and innovation for which Leigh is known.

The Basics

The Leigh R9 PLUS Joinery System really brings the long-admired Leigh CNC (computer numerically controlled) machining to an affordable product. The Leigh R9 PLUS Joinery System helps you make 3 sizes of box Joints in boards up to 1''-thick with finger sizes 3/16'', 3/8'' and 3/4''. You can also make 3 sizes of through dovetails in boards up to 13/16''-thick. You can make 3 pin widths - 3/8'', 7/16'' & 1/2'' and 2 joint pitches, 1 1/2'' & 3/4''.

|

|

You have to build the beam (left) bit it is very basic woodworking and Leigh includes the needed hardware. Leigh also supplies bits, the eBush, collet reducer and clamps (right) that let you make joints as soon as you make the beam. Click images to enlarge |

|

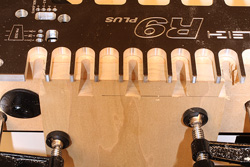

Adjusting the fit of dovetail or finger joints has baffled woodworkers for as long as there have been joints. Trying to make those adjustments on a long board was even worse. Along comes Leigh with their innovative eBush and perfect-fitting joints is easy for veterans and new woodworkers alike. Again, there are no adjustments to the jig itself, just very simple adjustments at the eBush.

One of the price-containing ideas was to use a shop-made beam on which to base the Leigh R9 PLUS Joinery System. Leigh does supply all of the high-quality hardware along with nicely done instructions that guide you through building the beam. This step does add some “setup” time but it saves you a bunch of money and it should last forever. And the beam is designed so that you can use the Leigh R9 PLUS Joinery System on the bench with your hand-held router or on a router table! Because of how the Leigh R9 PLUS Joinery System indexes on the pin plates you can make the beam and your joints as long as you like. There really are no limits to the length of the through dovetails and finger joints you can make.

The Leigh R9 PLUS Joinery System includes the R9 Template that has been beautifully machined from (6061 T6) aircraft aluminum before being anodized. You also get 3 pin plates and (patent pending) template positioning technology. (You can buy extra plates for very long jobs). Two F-style clamps equipped with anti rotation locators, an adjustable Side Stop, one No. 80-8 dovetail bit, 1/2'' x 13/16'' x 8'', one No. 160 straight bit, 1/2'' x 1-1/4'' and one No. 172-8, collet reducer, 1/2'' to– 8mm to fit the included 8mm bits. You also get the very trick, patent pending e10 elliptical guidebush for adjusting joint fit. All of the needed hardware for building the beam is included as is the typically well-done Leigh User Guide. I have been a fan of the Leigh User Guides since I bought my first dovetail jig and they have not slacked off on making their manuals the best that there is. The User Guide covers everything you need to know and makes following along as you set up your jig very easy.

|

|

The CNC'd plate (left) makes cutting perfect joints very easy. the setups use this array of machined holes (right) that do all of the mystery stuff in making these joints. Click images to enlarge |

|

You can also buy the R9 Plus Accessory kit that includes one #166, 3/16” spiral upcut bit (box joints), one #173, 3/8” spiral upcut bit (box joints), one #70-8 3/8” dovetail bit (through dovetails) one #75-8, 7/16” dovetail bit (though dovetails) one 140-8 5/16” straight bit (half pitch thought dovetails) and one e7 e-Bush that is used with the #70-8 and 75-8 bits for half-pitch dovetails.

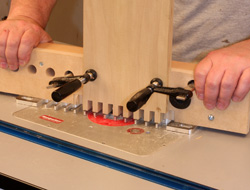

The Leigh R9 PLUS Joinery System is designed for use clamped to a bench or plate-side-down on a router table. Try that with most dedicated dovetail jigs! I initially thought that Leigh may have slipped a pin or something with a jig that can be used upside down but it absolutely works! And all of the supplied parts and pieces needed to use the Leigh R9 PLUS Joinery System in either configuration are included.

In the Shop

Because the Leigh R9 PLUS Joinery System is a fixed width jig you have to cut the wood to fit the joint that you want to make. The User Guide provides very detailed charts that make choosing the appropriate lumber width for your project.

Bench-Mounted

I followed the directions in the User Guide to set the Leigh R9 PLUS Joinery System up for through dovetails. I also installed the eBush that came with the kit and aligned the #5 position with the router so that it was aimed directly at the jig. Taking the time to get the eBush orientation right makes it easy to adjust the fit of the joint later.

|

|

The Leigh eBush (left) is a remarkable piece in how easy it makes adjusting joints that have raised the blood pressure of veteran woodworkers for decades! Cutting through dovetails with this system (right) is surprisingly easy and quick with just a little familiarization. Click images to enlarge |

|

After clamping the wood to the Leigh R9 PLUS Joinery System I marked the spots where I was to route. When making the tails you route between every other space so the chance for operator elevated so I thought actually marking the spots to be routed would minimize mistakes. That worked and I routed the tails right the first time and didn’t waste any wood.

Then I turned the plate around as per the instructions to set it up for cutting the pins. This time we route away all of the material between all of the fingers. The only caveat is that you need to be sure the eBush rides against the jig fingers all the way around to be sure all of the material is cleared out. I blow the debris out the cuts after the first pass and then go through them again just to be sure. I do this on all dovetail jigs because so much debris is generated that the bushing can be held away from the plate fingers. After going through all of the fingers a second time I took the wood out and tested the joint.

You can see in the photos (the actual first joint made) that there are tiny cracks when dry fit. If this was a project job I might tweak the eBush a tiny bit and re cut the joint but the cracks looked to be small enough that a normal film of glue would close them up. I brushed a bit of glue to the joint and it slipped together with no visible cracks. After sanding the edges flush the cracks were gone.

Router Table

The only change needed to the beam itself to use the Leigh R9 PLUS Joinery System on a router table is adding the included slider button that supports the free end of the beam to prevent rocking. It actually is hard to rock the jig with it resting on the large, flat plate but the slider button will help those who hold the beam that far out.

|

|

Using this jig on a router table (left) is at least as easy as when clamped to a bench. Because this is a fixed width jig you have to cut the wood to size (right) but charts in the User Guide makes this a snap. |

|

Actually, using the Leigh R9 PLUS Joinery System on the router table is easier than I anticipated. I put the eBush in the router insert plate and installed a 3/8” (Leigh HSS) straight bit and followed the setup instructions for positioning the plate to make box or finger joint. I installed the eBush with the #5 position aimed directly at the back of the router table so I could make changes to the joint fit easier if needed at all.

Incidentally, Leigh exploits the turning the Leigh R9 PLUS Joinery System upside down to use on a router table by printing the router table section of the User Guide upside down from the rest of the manual. Who says Canadians don’t have a sense of humor.

I clamped the wood into place, set the bit height and routed the fingers on the first piece. The plate gets moved to a new setting for routing the second set of fingers but the side stop stays the same. I routed that side out and tried the fit. It was just a little tight so I cut clean edges on the boards and turned the eBush one full increment towards “Loosen” as shown on the eBush itself and re-cut the joint. This time it fit nicely. The eBush really is a piece of joint-making magic when you can tune a box joint that easily!

Conclusions

The Leigh R9 PLUS Joinery System is another great idea from Leigh that is executed with all of their traditional CNC perfection. They really have figured this jig out so that it easy to use while maintaining the surprisingly low price point they were after. No the Leigh R9 PLUS Joinery System does not make variably spaced joints nor half-blind dovetails but those are the only real limitations. Since most people use through dovetails and finger joints far more than anything else, the Leigh R9 PLUS Joinery System covers a bunch of woodworking bases. Add the fact that you can make the beam virtually any length that you want and the Leigh R9 PLUS Joinery System will cut its joints on larger pieces of wood than many of the higher priced alternatives. That also means that you don’t have to buy anything additional aside from the pin plates to work with long joints.

Video Tour |

The Leigh R9 PLUS Joinery System is carrying a street price of $159.00 (11-16-2011). You do have to build the beam yourself but since we are woodworkers that is not a big issue especially when you consider the cost savings along with the flexibility of making the beam as long as you need it.

If you want a quality dovetail/finger joint jig that won’t kill even moderate budgets the Leigh R9 PLUS Joinery System is pretty much alone in that segment of the marketplace. The fact that it features Leigh’s CNC accuracy, high-end materials and always-great customer support should your decision way easier. Take along hard look at the Leigh R9 PLUS Joinery System before you waste money on something else.

Visit the Leigh Jig web site – Click Here

Have a comment on this review? –Email Me!

All written, photographic and drawn materials are property of and copyright by NewWoodworker.com LLC 2000-2019. Materials may not be used in any way without the written permission of the owner.