This is a Veteran Owned site

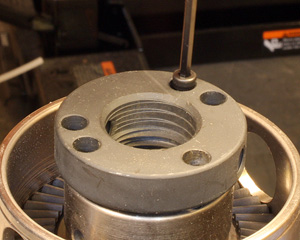

Oneway Talon Safety Scroll ChuckBig holding power, friendly designText, photos and video by Tom Hintz Updated - 7-30-2012 Chucks for lathes have been a favorite accessory about as long as the lathes themselves but it took a while for the manufacturers to devise the modern safer, more user-friendly designs. The Talon Safety Scroll Chuck is made by Oneway Manufacturing (Stratford, Ontario, Canada) is one of the most popular chucks on the market because of its quality, remarkable holding power and ease of use in a safe, versatile package. The BasicsThe Oneway Talon Safety Scroll Chuck is impressive right out of the box. Top-notch machining, high-quality materials and flawless assembly produce a smooth operating unit. Closer inspection of the operating mechanism shows careful attention to function and durability. Subtle things like the multiple V-groove keyways that insure smooth, accurate movement of the jaws benefit the user for the life of the chuck while complicating manufacturing processes to produce it. But, Oneway has a reputation for caring far more about building high quality products way more than cutting production costs. The Oneway Talon Safety Scroll Chuck comes fully assembled except for having to install the spindle thread adaptor to fit your lathe. While most chucks use thread-in adaptors, the Talon's Taperlock adaptor fits into an ultra-precise taper in the chuck housing, secured with three Allen screws that help to seat the adaptor in the taper firmly. Two additional, tapped holes in the adaptor accept two of the mounting screws that are then used as jacks should removing the adaptor become necessary. If you have ever fought with something stuck in a taper you will love this simple but hyper-effective jackscrew idea for curing that problem.

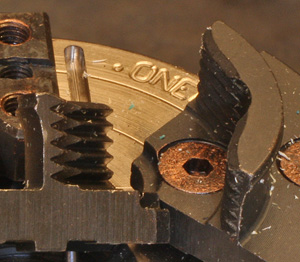

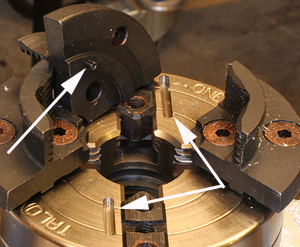

The instruction booklet packed with the Oneway Talon Safety Scroll Chuck is well written and augmented with high-quality illustrations. In addition to clear instructions for preparing it for installation, the manual also provides extensive information on using the Oneway Talon Safety Scroll Chuck effectively and safely. Jaw DesignOneway developed what they call a "wave pattern" for their Talon Safety Scroll Chuck jaws that dramatically increases the contact points (and their effectiveness) around a spigot while being less dependent on its diameter. The Oneway Talon Safety Scroll Chuck comes with a set of #2 jaws installed that have a grip range of 1 5/8" to 2 7/8" externally (spigot) and 2" to 3 ½" internally (recess). Oneway has a full range of accessory jaw sets available to fit virtually any job that bolt right up to the Oneway Talon Safety Scroll Chuck. The outsides of the jaws are designed to grip the inner edges of a slightly tapered recess where the maximum amount of wood is available. Unlike other jaw designs that require the recess walls to have a 7-degree (or steeper) taper, the Oneway Talon Safety Scroll Chuck jaws need only 2 to 3-degrees of taper for maximum grip strength. That means recesses are easier to cut with standard tools. Unlike some chucks, the jaws on the Oneway Talon Safety Scroll Chuck can be installed at random with the exception of the one with the extension-limiting pin. The Oneway Talon Safety Scroll Chuck allows you to use this safety pin to limit the outward travel of the jaws. Two different length-limiting slots are machined under the #2 and #4 jaw positions that interact with the single pin pressed into one jaw. Installing that pinned jaw in the desired limiting slot is all it takes to change the Oneway Talon Safety Scroll Chuck from full to reduced jaw extension. Limiting jaw extension by putting the pin in the shorter slot is a safety feature meant originally for school environments that can also be used by beginning turners. The short slot prevents the jaws from hanging out from the body and thereby reducing the chance of banging up knuckles or tools on their ends. With the pin in the long slot, full extension of the jaws is permitted but prevents them from scrolling off the body entirely. This setting is for veteran turners who are more familiar with working close to the chuck.

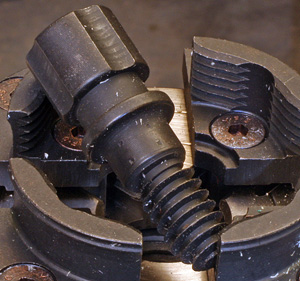

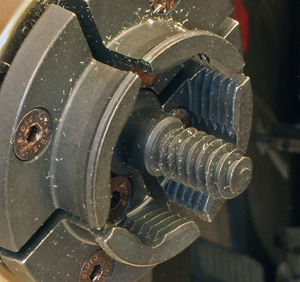

The jaws have a curved, tapered key that locks them into the sliders securely. The fit of this key is very precise and eliminates unwanted movement between the jaw and slider. All four jaws are operated by turning a single key, inserted through either of two access holes in the body. The fit of the keys one-piece gear and shaft to the internal ring gear is positive but easy to engage. Because gear is machined into the shaft rather than added to it on a swivel, potential failures of a swivel pin are eliminated. The combination of an easy-to-use scroll key and good gear ratio between the key and ring gear means securing even large work pieces in the Oneway Talon Safety Scroll Chuck jaws is quick and easy rather than a test of strength. Woodworm ScrewIncluded in the Oneway Talon Safety Scroll Chuck kit, their Woodworm screw makes mounting bowl and many other blanks a simple but secure task. Used primarily for initial rounding and shaping, the Woodworm screw allows more extensive turning of the outside surface on many projects than could be accomplished with the piece between centers. The design of the Woodworm screw (developed by Oneway and copied by many others) provides a surprising amount of holding power. The base of the Woodworm screw is machined to match the internal surfaces of the Oneway Talon Safety Scroll Chuck jaws to prevent it from spinning inside the chuck. The base of the Woodworm screw also engages a lip on the jaws to further secure it, preventing unwanted and potentially dangerous movement during use. If it is installed correctly there just is no way for the Woodworm screw to fall out. You do have to drill a 11/32” (9mm) hole about ¾”-deep into the blank but after that the Woodworm does the real work! In The ShopAfter installing the Oneway Talon Safety Scroll Chuck on my lathe, the Woodworm screw was clamped in the jaws and a bowl blank (about 8”-diameter) was drilled and threaded onto it. Although it is normally my practice to also use the tailstock and live center to stabilize the blank during initial rounding when most of the out of balance mass is removed I went with the Woodworm screw alone. I wanted to show the holding power this screw has but aside from this demonstration it is easy and advised to bring the tailstock up and add that support to the blank at least initially.

The Woodworm screw held tight throughout the rounding and shaping process on the outside of the bowl. To complete the outside of the bowl I flattened the bottom and cut a recess for the Oneway Talon Safety Scroll Chuck jaws. I do this with a normal ¼” parting tool held at a slight angle to the bottom. The idea is to cut a recess (about 2-3/4”-diameter) that is deep enough to give the chuck a good grip but shallow enough so that the jaws bottom out before the rest of the bottom surface contacts the face of the jaws. I usually cut this recess to about 3/8” deep and that has worked fine for me. After removing the blank from the Woodworm screw, the blank was turned around and the tenon clamped in the jaws. The blank once again turned very true and needed very little cleanup to make it perfectly round in the reversed position. Throughout the hollowing process, the blank remained tight in the jaws with no adjustments to clamping position or pressure needed along the way. It has been my experience that short of a major catch the piece will not have to be repositioned during the rest of the bowl-making process when using the Oneway Talon Safety Scroll Chuck. I do check the jaws once in a while to be sure they remain tight, just for peace of mind. I have never found them to be loosening up. I have also clamped various square and round stock in the Oneway Talon Safety Scroll Chuck using the standard jaws that come with it. With some larger stock it is necessary to turn a short tenon but the jaws are designed to get a firm grip that way as well. You can also turn a tenon onto the bottom of a bowl during turning but most opt for the recess which saves overall finished bowl height. I have never felt like the Oneway Talon Safety Scroll Chuck slipped without cause – like a big catch which would be my fault anyway. ConclusionsThe Oneway Talon Scroll Chuck is a top-notch tool with many desirable features that make it effective and safe for woodturners of all experience levels. Ease of use and durability are designed into the Talon, insured by high-quality materials and precision. With common sense use and care on your part there is no reason why the Oneway Talon Safety Scroll Chuck won’t last as long as you do in the shop.

With a street price of $226.95 (7-30-2012) for the Oneway Talon Safety Scroll Chuck with #2 jaws and $31.49 for the threaded insert to fit your lathe this chuck is a good deal as well. I used my first Oneway Talon Safety Scroll Chuck for well over 7 years without out an issue and it is now being used by someone else! I am confident that I will get the same useful life from my new Oneway Talon Safety Scroll Chuck because it is still made the same way with the same high-end materials and workmanship. Visit the Rockler Talon page – Click Here Do you have a comment about this page? - Email Me!

|

||||||||||||||||

All written, photographic and drawn materials are property of and copyright by NewWoodworker.com LLC 2000-2019. Materials may not be used in any way without the written permission of the owner.