This is a Veteran Owned site

|

The Powermatic PM2000 is easily the best table saw I have ever used, seen or heard anything reliable about. Click image to enlarge |

POWERMATIC PM2000

I had (most of) the rest, now I have the best

Text, photos & video by Tom Hintz

Posted - 6-27-2007

Special Sneak Peak!

In over 30 years of woodworking I have had several very good contractor-style table saws but wanted to make the jump to a high-quality cabinet saw. To save money I wanted this to be a one-time jump. After watching several woodworking forums for new cabinet saw owners and talking to several, it became clear that the happiest folks I could find had a shiny new POWERMATIC PM2000 in their shop. I also discovered that the POWERMATIC PM2000 is the best selling machine in the very large and very popular POWERMATIC line. I would find out that there is good reason for that.

The First Amazement

Everything I had heard about the POWERMATIC PM2000 suggested a big, heavy piece of machinery. When the trucker rolled the skid carrying the main cabinet assembly (nothing else, there were more skids...) onto the lift gate and it drooped noticeably, I was very impressed. I was also happy to be leaning on my hydraulic shop crane, as it was obvious that all of this cast iron was far beyond my normal grunt and strain assembly routine.

Tip: Unless you have a forklift, I strongly suggest having the POWERMATIC PM2000 delivered on a lift gate truck. It is far easier - and safer - to handle if you begin with the skid on the ground.

Assembly

Actually building the POWERMATIC PM2000 turned out to be easier than I anticipated. The toughest part of the process was getting the POWERMATIC PM2000 off of its shipping skid. My shop crane made that a far safer task then me trying to hustle it to the floor. Once off of the skid, assembling the POWERMATIC PM2000 was easy and surprising fast. I was able to assemble the POWERMATIC PM2000 by myself and go through a complete alignment check in one day.

All of the parts fit perfectly, the fastener bags had the correct number of pieces and the instruction manuals guided me through assembly without confusion or backtracking. The substantial amount of factory assembly greatly reduced my skid to cutting wood time. Even the wiring was complete with the exception of installing a plug on the end of the cord to match my 220V outlets.

The Look of Quality

|

Powermatic certainly did not spare materials or labor when making the cast iron handwheels and forged steel locking pins. These are real machine parts, not something made to simulate the real thing. Click image to enlarge |

One of the first things I noticed about the POWERMATIC PM2000 is that everywhere I looked there was evidence that POWERMATIC intended this to be the best table saw. Their choice of materials and machining processes clearly suggest that quality, durability and function were given higher priority than manufacturing cost.

Most noticeable are the 30-1/2"-deep (front to back) cast iron table and the large, cast iron hand wheels that operate the blade height and bevel mechanism. The chromed outer rims, painted centers and finely machined forged steel locking pins could easily have been replaced with stamped, cast or plastic parts to save a bunch of money - but weren't.

The massive cast iron base alone is out of the ordinary to say the least. Add the retractable caster system built into it and the POWERMATIC PM2000 zooms into a world of its own.

The Operating Mechanism

|

|

(top) The arbor is housed a huge chunk of cast iron and rides in high-end ball bearings. Vibration is non-existent.. (bottom) The arbor accommodates stacked dado sets at their full 13/16"-widths. Also, notice there is no dip between the threads and the shank of the arbor that can let dado plates hang down out of line with the rest. Click images to enlarge |

Within the heavy gauge steel cabinet is an all cast iron, box-style mechanism. Though known to be a very rigid, stable design, POWERMATIC added even more cast iron just to be sure. They also devoted extra design and manufacturing time on the gear drives that operate the height and bevel functions. The gearing is smooth operating right out of the box but more importantly stays that way when the saw is used and dust builds on these parts. The gear mesh is designed to operate freely in this environment and does just that. A lash adjustment is built into the gear system so when years of use begins to create a little extra play, the owner can adjust it back to factory-fresh clearance and feeling.

The blade arbor is mounted in a huge piece of cast iron and set in equally large, high-quality ball bearings. Power is sent from the motor to the arbor through a wide Poly-V belt that drives a pair of fully machined aluminum pulleys. The result is ultra smooth power, no vibration and little heat buildup at the bearings. That translates into an exceptionally long life for these expensive parts.

The arbor itself is 5/8"-diameter and protrudes outside of the rear blade washer a full 1 3/8" to accommodate most stacked dado sets at their full 13/16"-width. The arbor threads are cut so that there is no dip between them and the shank. This dip is found on most table saw arbors and can allow thin dado stack chippers to hang out of alignment with the rest of the plates and cause an irregular bottom to the dado they cut.

In keeping with the POWERMATIC edict that big is better, the blade washers and nut are large and heavy duty. Their heft is due in part to the 3hp motor (5hp is available) and at least partially to appease the POWERMATIC penchant for lots of metal. Also, the insert throat opening is a huge 17-7/8"-long and 4"-wide to make access easy.

Blade Changing

|

|

(left) A simple pushbutton arbor lock makes changing blades simple and safe. (right) The full-sized combination wrench is meant to make tightening or loosening the blade nut easy, not to see if you can use all of the leverage to break something! Click images to enlarge |

|

The POWERMATIC PM2000 features a push button arbor lock that engages large machined notches in the rear blade washer. They also include a full-sized, (13 1/4"-long) forged steel, 27-mm combination wrench. The only problem with this system is that the wrench provides enough leverage for the "never-too-tight" crowd to overpower the arbor locking tab and possibly shear it off. The full-sized wrench is intended to make tightening or loosening the blade nut easy and it works great when the operator does not perceive blade changing to be a test of strength.

Dust Collection

|

This shroud captures an extraordinary amount of dust and then sends it to the 4"-diameter external port through a flex hose within the cabinet. Click image to enlarge |

A specially designed shroud wraps around the lower portion of the blade. That shroud is connected to the exterior port via a flex hose within the cabinet. The exterior port, located on the lower rear face of the cabinet accepts common 4" dust hoses.

A nice feature of the connecting hose is that it can be removed from the shroud or exterior port should you drop the blade nut into the shroud. If you have used a table saw for more than a month, I suspect you will appreciate this seemingly insignificant feature.

Motor and Switch

My POWERMATIC PM2000 is equipped with a 3 hp, 220V (1-phase) motor. POWERMATIC claims they rate their motors based on actual continuous duty horsepower, not the always-suspicious "peak" or "developed" power rating system. My experience with POWERMATIC machines does nothing to refute that claim. Using the POWERMATIC PM2000 for some time now makes me wonder if they aren't underestimating power a little.

Controlling all that power is an all-new magnetic switch that does more than turn the motor on and off. It offers protection from low voltage conditions that are often accompanied by amp spikes that could jeopardize the motor.

|

|

(left) The 3hp motor is large and has more power than I have yet to need. It is also very smooth-running. (right) The magnetic switch guards against motor damage and prevents the PM2000 from restarting on its own should the power go out and come back on.

Click images to enlarge |

|

A major safety feature of magnetic switches is that once electrical power is interrupted, the saw will not restart by itself when the power comes back on. If power is interrupted, the operator must physically push the on button to get it to start.

The POWERMATIC PM2000 switch has a large red Off ring that is easily pushed by hand or bumped off with your leg. In the center of that ring is a green lighted button that turns the saw on when depressed. The green light within the On button simply shows that the machine is connected to electrical power.

Above the On/Off switches is a yellow disk that contains a strong magnet. This is the disabling "key" that lets you be sure no one else is going to start the POWERMATIC PM2000 without you around. Simply remove the yellow disk and the switch is rendered inoperative. You can carry the yellow "key" in your pocket or use its magnet to stick to a handy metal surface in the shop.

Trick Blade Guard

|

|

(top left) The side plates of the blade qua rd are independent, adding another layer of protection and enhancing dust collection. (top right) In seconds the blade guard can be removed with the push of a button. (right) The anti-kickback pawls are also on a push button release and can be removed so the throat plate will come off over the remaining splitter plate. Click images to enlarge |

|

One of the more ingenious engineering feats on the POWERMATIC PM2000 is the modular blade guard system. This guard can be removed without tools in seconds for changing blades.

The guard itself is actually two separate plates, one on either side of the blade. Both plates are mounted on pivot arms so they work independently. Plus, they can be rotated up out of the way for measuring cut widths. When making a narrow cut, only the plate over the wood rises off the table. The other plate stays flat on the table to prevent chips or debris from being kicked out. Leaving the other plate on the table further limits escaping chips and enhances the already very effective dust control.

The POWERMATIC PM2000 blade guard system is modular in that the guard plates, anti-kickback pawls and splitter are separate assemblies. The guard plate and anti-kickback pawls can be removed individually by simply pushing the release button on their mounts. That leaves the splitter with nothing on it so the throat plate can be removed for blade changing. The splitter mount is also tool-free and requires only a flip of its locking lever to remove or install the splitter.

|

|

Standard and thin kerf riving knives are available and fit in the same no-tools mount (right) as the factory splitter. Changing them takes seconds. Click image to enlarge |

|

So much for your "too much of a hassle" excuse for not using the factory safety equipment.

The splitter mount is connected directly to the arbor boss so it follows the blade through height and bevel changes precisely. That includes the important gap between the blade and splitter leading edge, which remains constant - and correct - when you crank in a new blade setting. Riving knives, available as accessories use the same mount and also remain aligned with the blade.

Accu-Fence

If you are one of the legions of woodworkers who believe a table saw is only as good as its fence, the POWERMATIC PM2000 wins again. Once again, POWERMATIC stepped up the engineering and manufacturing to make sure the Accu-Fence works perfectly out of the box and forever thereafter.

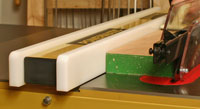

|

|

(left) The Accu-Fence is solid, easy to use and repeats better than any fence system I have used. I set it up during assembly of the PM2000 and it has not required adjusting since! (right) The HDPE fence faces are very slick without waxing, don't react to moisture and stay straight. You can also adjust them up and down if you like. Click images to enlarge |

|

The Accu-Fence is built from heavy-gauge steel but so are some other high-end systems. POWERMATIC steps ahead of the pack because they mill the face-mounting sides of the main tube to be sure the face pieces are straight when applied. This eliminates having to shim them to be reasonably straight, as is the case on most other saws.

POWERMATIC also chose to forgo the common laminate-covered wooden faces and instead use 3/4"-thick HDPE (high density polyethylene) slabs that are far more costly but decidedly more stable and inherently slick. Both HPDE faces can be adjusted up and down to either run flush with the table surface or slightly above it to best fit the job at hand.

The Accu-Fence locking mechanism parts are made using the high-tech powdered metal process that creates highly precise and very strong pieces that have an exceptionally long life expectancy. The single operating lever works very easy but locks the fence in place securely.

The heavy steel T-square portion of the Accu-Fence has adjustments for squaring the faces to the table surface vertically and for aligning it to the miter slots. Smooth-running pads under the T-square section and under the end of the main fence tube mean the Accu-Fence slides effortlessly along its guide tube and the table surface.

Miter Gauge

|

|

(left) The standard miter gauge has lots of aftermarket features, like guide bar expanders, a repositionable fence and bolt slots. (right) They also threw in a trick gear drive for adjusting the fence angle. Click images to enlarge |

|

Even the miter gauge included with the POWERMATIC PM2000 goes beyond the norm. POWERMATIC took several of most-wanted features woodworkers sought in aftermarket miter gauges and built them into the one they supply with the POWERMATIC PM2000.

The guide bar has the typical T-slot follower disk but also sports a pair of expander slots that allow fine tuning its width to the miter slot. A couple tweaks with a hex wrench and the inaccuracies of side-to-side play are gone.

The oversized 12 3/4"-long by 2 3/4"-tall extruded fence has slots on the face and top edge that let you use bolts to fasten shop-made faces or fixtures. The miter head pivots 60-degrees to the left and right and has positive stops at 0-30 and 45-degrees to either side. POWERMATIC added a nice little gear drive, operated by pulling out and turning the locking pin that makes it easy to dial in the exact setting wanted.

The fence face can also be adjusted closer to or farther from the blade by simply loosening a pair of finger-operated levers, slide it to the new setting and lock down the levers. This is an important safety feature because it lets you set the fence close to the blade regardless of the angle. That makes controlling the wood easier in mitering situations.

Mobility

|

If it appears that the PM2000 is floating, that's because it is, on hidden retractable casters. You will be floating yourself when you float a 700-plus pound machine around the shop without straining anything. Click image to enlarge |

Being able to move large machines within the shop is important to many woodworkers. When that machine has a 50" fence system and weighs 700-plus pounds, moving it can be a major (or dumb) chore. The folks at POWERMATIC have obviously had to hustle a large machine around before and added an ingenious retractable caster system to eliminate that kind of strain for POWERMATIC PM2000 owners.

The caster system is built into the cast iron base and remains fully within it. Non-marring polyurethane tires are mounted on heavy-duty ball bearings and allow the POWERMATIC PM2000 to glide easily from one place to another. All four casters swivel freely so the POWERMATIC PM2000 can be moved in any direction, including spinning in circles which comes in very handy when there isn't room to "steer" a 50" fence to where you need to go.

The casters are extended and retracted by pulling the bevel wheel out to engage the caster drive. The total lift is approximately 1/2" which is plenty for all but the most uneven of floors.

One of the really nice things this caster system is that when retracted the cast iron base rests solidly on the floor with all of the stability you would expect from a 700-pound machine. With mere mortal mobile bases, the wheels may lock to some degree but the saw remains perched on the tiny contact patches of those wheels.

In the Shop

|

One of the first jobs for my new PM2000 was trimming and squaring a little over 40 feet of 2"-thick oak. Turns out the PM2000 couldn't have cared less. It continued to hum along like always. Click image to enlarge |

After using the POWERMATIC PM2000 for a couple months the quality and design of this machine became very clear. Despite the remarkable power available, this saw purrs smoothly. Vibration is non-existent. Even the blade height and bevel mechanisms feel remarkably different. They are smooth but do not have that "loose" feeling when turning the hand wheels. Dialing in the exact change wanted is simple and then turning the locking knob freezes that setting with no creeping or changes.

The power and Poly-V-belt drive simply fear no wood. Install a sharp blade and the POWERMATIC PM2000 sliced through whatever wood I had, including 2"-thick oak without a whimper. Lay the blade over to a 45-degree bevel and it cuts just as cleanly and without a hint of binding. The stability of the massive cast iron mechanism means that when laid over at 45-degrees, the weight of the motor does not pull the blade out of alignment as so frequently happens on lesser machines.

The Accu-Fence is a pleasure to use because it is actually straight and holds alignments very well. The locking lever and mechanism is deceptively easy to operate. So little effort is needed it made me wonder if the Accu-Fence was actually locked - it was.

|

The 50" Accu-Fence comes in handy when sheet stock has to be trimmed or reduced. Even with all the leverage big pieces of sheet material can generate, the cuts were straight every time. Click image to enlarge |

The adjustments for squaring the faces to the table and the fence to the miter slots are easy to use and effective. Since adjusting the Accu-Fence during assembly I have rechecked it several times and have yet to find a measurable change.

The HDPE faces are inherently slick and stay that way without having to apply wax or other preparations. Moving even thick wood along them is effortless, smooth and very predictable. That enhances accuracy and safety.

The modular blade guard and splitter system is absolutely inspired. This is a very well made system that in no way hinders making cuts but offers the best protection I have seen on a table saw. With the addition of an accessory riving knife, the POWERMATIC PM2000 can be configured to make virtually any cut with a high degree of accuracy and safety.

The independent guard plates not only help prevent debris from flying out but also contain dust so it can be evacuated by the hyper-effective dust system built into the POWERMATIC PM2000. Connect a good dust collector and the wrap-around shroud below the blade strips nearly all of the dust as it is generated. I was shocked at how little dust wound up on the table surface, even when cutting very thick material.

See It Work! |

The retractable caster system may be the most ingenious feature on the POWERMATIC PM2000. I had serious doubts about its effectiveness until I used it. Lower the casters and this 700-lb machine floats across the shop floor. With the 50" fence system, being able to move the POWERMATIC PM2000 in whatever direction is needed makes negotiating our smaller shops very easy. Retract the casters and the POWERMATIC PM2000 rests firmly on its cast iron base, now fully in contact with the floor. The result is the stability of a permanently installed machine with the convenience of a portable machine but none of the liabilities.

Beginners Saw?

One of the more twisted things about woodworking is that beginners are too often saddled with low-priced machines that are more difficult to operate, keep aligned and frequently have hard to use safety features. Learning on the POWERMATIC PM2000 would be far easier because it does not force the new user to compensate for cost-saving features, materials and manufacturing. Before long, most new woodworkers are seeking a "better" table saw and begin a progression through saw upgrades that eventually costs far more than buying a POWERMATIC PM2000 the first time around.

The reality is that a beginning woodworker will learn faster and safer, plus save money over the long term with a quality machine like the POWERMATIC PM2000. They will also develop into a safer woodworker because the POWERMATIC PM2000 safety features work so well that their removal has no benefit to the quality or speed of the woodworking.

Conclusions

With a street price of $2,299.99 (6-26-2007) the POWERMATIC PM2000 represents a major investment but one that will pay dividends literally for the rest of your life - and someone else's because this machine is designed and built to perform perfectly now and for many, many years to come. The POWERMATIC PM2000 is very powerful, dead on accurate and stays that way.

I realize we all have budgets to work within and the POWERMATIC PM2000 would be a major hit. However, considering the quality of this machine and the array of features, plus the near indefinite life span, buying a POWERMATIC PM2000 for your shop would be a wise and welcome investment.

The POWERMATIC PM2000 is easily the best table saw I have seen and by far the best value. Whether you are looking to upgrade from an existing saw or just want to make the best investment the first time around, the POWERMATIC PM2000 should be at the top of your list. In my opinion, it should be the only saw on that list.

Have a comment on this review? - Email Me!

All written, photographic and drawn materials are property of and copyright by NewWoodworker.com LLC 2000-2019. Materials may not be used in any way without the written permission of the owner.