This is a Veteran Owned site

|

If I had CNC equipment and a bunch of time I might be able to make this jig myself. Until then, Rockler has the best alternative! Click image to enlarge |

Rockler Pro Shelf Drilling Jig

How I would have made it (if I had CNC machines, skill, time, etc.)

Text, photos and video by Tom Hintz

Posted – 10-11-2010

Woodworkers have conjured up all sorts of home-brewed whirligigs for making shelf pin holes. The old standby has been pegboard but the holes wear and expand so quickly that before you know it the holes can be spaced a little differently at one end than the other on the same jig. I personally have had several homemade jigs, a few factory made cheapies that used drills or routers but I never found one that I liked. Until now that is. The Rockler Pro Shelf Drilling Jig does what I want and even more importantly it does it consistently where I want. When I saw the price of buying the Rockler Pro Shelf Drilling Jig, (that actually works) thinking about what I spent over the years on “almost” jigs made me a little sick.

The Basics

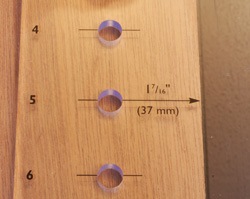

The Rockler Pro Shelf Drilling Jig is an acrylic plate and aluminum channel device that makes shelf pin holes in stock from 8-1/4” to 25-1/4” wide and as long as you care to make it. Each of the 1/4”-thick acrylic plates have a center hole with 8 equally spaced holes above and below that. The holes are precisely 32mm or1-1/4” apart and set in 37mm or 1-7/16”from the guide rail edges. These spacing’s are compatible with the popular Euro hinge systems.

|

|

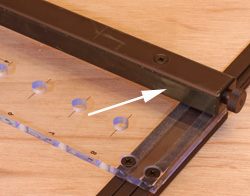

The guide holes (left) are perfectly aligned and spaced. That is the secret of how this jig works and why it is all but impossible for us to do build this in our shops! The guide bars (right) can be installed with the smooth metal surface or the rubber stripped side (arrow) facing in. I chose the later and that seems to be working out for me very well. Click images to enlarge |

|

The Rockler Pro Shelf Drilling Jig comes needing some assembly but that is simple enough that the instructions are on the box itself. To make assembly foolproof the right acrylic panel has 4 mounting holes and the right panel has 8. (Let’s see you get those backwards!) You get one hardware bag and everything is self-explanatory enough that following the simple instructions I had the Rockler Pro Shelf Drilling Jig ready to work in less than 15 minutes. Keep in mind that I have to stop and take photos and video in that time as well. I expect you can be ready in less time if the rush is on.

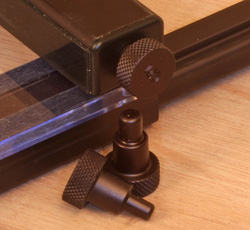

The only real choice you have during assembly is to install the guide rails with the rubber strip facing in or out. Put the rubber strip facing in and the jig grips the wood very well. Install the guide rails with the smooth metal side in and the jig can slide along long pieces more easily. I chose to put the rubber strip facing in and so far that seems to have been a decent decision. The sliding sizing channels at the top and bottom each have a single locking knob so adjusting the Rockler Pro Shelf Drilling Jig for your work piece is closing in on instantaneous.

In addition to the necessary assembly hardware the Rockler Pro Shelf Drilling Jig comes with four machined alignment pins – two ¼”-diameter and two 5mm-diameter. These pins are used when you need to make rows of shelf pin holes longer than the jig. You simply drill one set of holes, slide the jig to the next position and use the pins to index it to the last holes in the set you just drilled. With these pins you can drill perfectly spaced rows of holes as long as you need. The alignment pins store in receptacles in the ends of the guide rails when not in use.

In the Shop

|

|

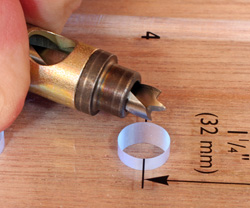

These alignment pins (left) are included and allow making rows of holes as long as you like without losing the accuracy of the spacing. I used the special bit that (right) which has the bushing that fits the holes and has a very good brad point bit within to cut clean holes. Click images to enlarge |

|

The Rockler Pro Shelf Drilling Jig is simple enough to use that the major decision you have is to decide where you want to start and stop the shelf pin holes. My normal plan is to mark the center of the area that needs the shelf pin holes and align the centerline of the Rockler Pro Shelf Drilling Jig with that. You can start with the one end of the Rockler Pro Shelf Drilling Jig a comfortable distance from one end of the work piece if that suits your job better.

With the rubber strips on the guide rails facing in the Rockler Pro Shelf Drilling Jig does get a good grip on the wood if you squeeze it a bit while tightening the knobs at the top and bottom. I find that adding a simple hand clamp at one end of the Rockler Pro Shelf Drilling Jig and drilling from the other end allows me to install the alignment pins just to be sure. You would have to bump the Rockler Pro Shelf Drilling Jig somehow to move it but when drilling these holes in an expensive piece of wood, the few seconds it takes to put a speed clamp in place for additional insurance is well worth the effort.

During the evaluation I drilled shelf pin holes in every piece of scrap that I could fit the jig on. Every one of them came out perfect with the sides perfectly aligned to each other side-to-side. The holes were also perfectly spaced top to bottom. That is what we always wanted our shop made jigs to do but lacking CNC (computer numerically controlled) machining capability rocking shelves used to be just a fact of life. If you get rocking shelves with the Rockler Pro Shelf Drilling Jig, you really did something VERY wrong.

For this evaluation I used a Rockler self-centering bit with the quick connect shank. The nose of the bit has a stepped bushing that fits the holes in the Rockler Pro Shelf Drilling Jig precisely to prevent wandering of the bit and wear on the holes in the jig itself. I just locked that bit in my Bosch cordless drill and making long rows of shelf pin holes was as fast as it was easy. The holes this bit drills are very clean because it is a real brad point drill mounted in there! The holes in the accompanying photos were drilled in cheap Lauan plywood with a surface that frays very easily. After drilling the holes a light sanding removed what tiny frays remained before finishing.

Video Tour |

Conclusions

The street price for the Rockler Pro Shelf Drilling Jig is $79.99 (10-9-2010) and the centering bit shown in this reviews runs another $21.99. Not bad at all for a quality jig that brings a level of accuracy we just cannot build ourselves. The Rockler Pro Shelf Drilling Jig is rather light and easy to handle but it is built robustly to insure a long, fully accurate life in the shop. Setting up and using the Rockler Pro Shelf Drilling Jig is very easy and very quick letting you do more woodworking and less adjusting. The built in accuracy is remarkable, repeatable and the design of the jig makes it very hard to mess that up.

If you are tired of trying to drill accurate shelf pin hole arrays and still winding up with rocking shelves, the Rockler Pro Shelf Drilling Jig could be just what you need. If you are like me, the peace of mind knowing that I can drill shelf pin holes exactly where they are needed and in perfect alignment with each other is more than worth the price of the Rockler Pro Shelf Drilling Jig. The time and frustration saved is worth even more.

|

Visit the Rockler Web site – Click Here

Have a comment on this review? –Email Me!

All written, photographic and drawn materials are property of and copyright by NewWoodworker.com LLC 2000-2019. Materials may not be used in any way without the written permission of the owner.