This is a Veteran Owned site

|

Many people buy this saw for the innovative blade brake system only to find it that invention is wrapped in a world class table saw. Click image to enlarge |

SawStop Professional Cabinet Saw

There is way more than the safety here

Text, photos and video by Tom Hintz

Posted – 3-19-2012

See Part 2 of the SawStop Review - Click Here

This review has been a long time coming but it has been worth the wait. Before actually getting the SawStop Professional Cabinet Saw I wondered about the quality of the table saw that was wrapped around the now famous blade-stopping system. That cartridge is a huge safety break though to be sure but to be of value to the woodworker the rest of the machine has to be useful as well. It turns out that in addition to the ground breaking SawStop brake system, they also engineered an awesome table saw to go with it!

The Basics

The SawStop Professional Cabinet Saw is a 3HP, 230V, 1 phase, 13 Amp saw weighs in at 426-Lbs as tested with the 36” fence capacity. This is a left tilt machine with 3-1/8” maximum cut depth with blade at 90-degrees and a maximum 2-1/4” cut depth with blade at 45-degrees. Dado capacity is 8” (requires special brake cartridge) with 13/16” width capacity on a 5/8”-arbor. The motor power is sent through dual ribbed V-belts with the arbor belt being static dissipative – something that is important with the electronics mixed in with the very stout mechanicals. The heavily built trunnion is controlled by a pair of 7”-diameter cast iron hand wheels with spinner handles and center locking knobs.

I know that all sounds pretty run-of-the-mill and in terms of the basic descriptions, the SawStop Professional Cabinet Saw does have all of the standard features. But that basic description is pretty much where the comparison with “normal” table saws end. Even the shiny black painted cabinet with its flowing contours across the front show exceptional manufacturing quality. The packaging insured that my SawStop Professional Cabinet Saw arrived with no cosmetic or physical defects that I could find aside from one small fence scale tape that didn’t stick down right. SawStop made that right with no questions asked.

|

|

The internal structure supporting the blade and brake (left) is first rate and designed specifically for the application, not converted. Even the insert plate (right) has been given locking features at the front and rear to add another layer of protection for the operator. Click images to enlarge |

|

Inside the cabinet is a 4”-diameter dust hose from blade shroud to the 4”-port on the back of the cabinet. We also find color-coded (yellow) adjusting bolts for 0 and 45-degree blade limits. Access doors in the right side (operator view) and rear panels let you get at the all-important SawStop cartridge and other internal adjustments without having to take Yoga classes to get limber enough.

I chose to go with the 36” rip fence capacity on my SawStop Professional Cabinet Saw because floor space in my shop is more valuable than my decidedly infrequent need for a larger fence. However, you can get the SawStop Professional Cabinet Saw with a 52” capacity fence. These fences are based on heavy iron angles and a 2” by 3” steel main tube. The T-square style fence is also built around rugged steel components. The base of the T-square features two repositionable magnified lenses that make aligning the fence to the clearly printed scales easy. There are individual scales for using the rip fence to the right and left of the blade which makes it much easier to do accurately.

The locking system on the SawStop Professional Cabinet Saw fence is very easy to use and adjust but remain very secure. The sides of the fence arm have 2-5/8”-tall laminate covered faces with slick surfaces to keep the wood moving predictably. The rectangular shape of the fence makes it easy to build your own jigs for specialty operations.

Industrial Mobile Base

|

|

The Industrial Mobile Base (left) is the best, easiest to use that I have ever seen. You easily move this saw in any direction! The top pedal (right) raises the saw for moving. Stop on the "Lower" pedal and the saw gently sinks to the floor to keep it stationary for use. Click images to enlarge |

|

Mobile bases have been around for a long time but I should have known that SawStop would do something cool in that genre as well. Their Industrial Mobile Base has four high-end full-swivel 3”-diameter casters and that alone is a bit different these days but there is much more. Rather than frustrating wheels locks SawStop came up with a hydraulic system that lets you literally pump the SawStop Professional Cabinet Saw up off of the ground with your foot so it can be moved in any direction needed. Then you step on the “Lower” pedal and the saw gently sinks down to the floor.

The hydraulic system is actually built around a bottle jack, a design that has been around for over 100 years. They engineered some linkage that uses the jacks’ power to lift and lower the saw and then did a great job of manufacturing the base. I have had a bunch of mobile bases under table saws in my time and can say with certainty that the Industrial Mobile Base is the best I have ever used, easily. If you can’t find me some time I might be out in the shop raising and lowering my SawStop Professional Cabinet Saw in that Industrial Mobile Base. Yeah, I’m fascinated.

Assembly

|

|

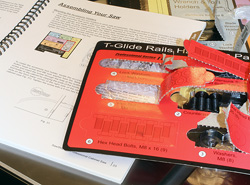

If you make use of the well done instructions (left) putting this machine together is easy. I checked the factory setup of the table (right) and it was well under 0.001" out from parallel to the miter slot. I left it alone. Click images to enlarge |

|

When I unpacked the SawStop Professional Cabinet Saw I was amazed at the money spent on high-quality instruction manuals that go way beyond satisfying basic legal requirements. These manuals are thorough, well illustrated and easy to follow. There are several manuals and even large printed instruction cards similar to those “Getting Started” posters that come with computers. If you have problems assembling or using the SawStop Professional Cabinet Saw you simply are not reading the provided literature.

The hardware is assembled in blister packages with everything labeled as they are referenced in the manuals but also for where they go. I think this labeled hardware packaging to be sort of a failsafe “this goes here” in case you really weren’t paying attention when reading the manuals. SawStop also includes a selection of hex wrenches, a long ball-tipped hex wrench and specify what other wrenches you will need as you go through the instructions.

While I was putting the SawStop Professional Cabinet Saw together I began finding more impressive engineering features that aren’t easily seen in the finished machine. One is the bracket under the edge of the extension table where it meets the cast iron wing. This has been a sore spot in many a table saw build because the table either sagged (most often) or bowed upwards and there was no good way to correct it. The SawStop Professional Cabinet Saw has a bracket that actually screws into the extension table and the cast iron wing so you can literally dial out the problem.

|

|

The fence system is very well built, locks easily and has dual repositionable cursors (left) that allow using the fence on either side of the blade. This little piece (right) makes adjusting the center of the extension table and the wing very easy and shows that somebody was thinking all the way through designing the SawStop Professional Cabinet Saw. Click images to enlarge |

|

The throat insert plate is totally different from anything I have used. It has a pair of screw heads at the leading edge of the insert that slip under mating screw heads in the cavity to lock down the front of the insert. At the rear is a bail-like arm that when pushed down, locks the rear of the insert in place.

The blade guard is also very different. It has a large main blade cover but also has independently operating side plates to the left and right. It has two levels of anti-kickback pawls and a deep splitter that actually keeps the kerf open behind the blade. The blade guard also has a 1-1/2“-diameter dust port at the rear that helps the in-cabinet collection to grab as much dust as is physically possible. The only way to have less dust around the shop is to not cut anything.

Atop the blade guard is a pair of arms and an aluminum nose that projects out in front of the guard assembly. This ingenious arm is actually a stop that prevents wood that is thicker than the blade is tall from entering the guard at all. If you have ever got yourself into this situation on a mere mortal table saw you know that there is no reliable way to get out of it. You can hold on and hope the saw shuts down without kicking the wood out or you can run but neither is as good of a solution as this stop on the SawStop Professional Cabinet Saw that keeps you from getting into the situation in the first place.

The SawStop Professional Cabinet Saw also comes with a riving knife that slips into the same mount that holds the splitter assembly. A single lever releases or locks that mount so changing from the riving knife to the blade guard system or back is fast, easy and tool free.

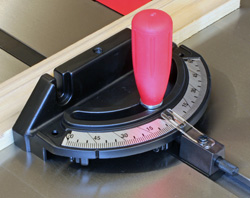

When I finished assembling the SawStop Professional Cabinet Saw I got out my dial indicator and checked the setup. The blade was well within 0.001” of parallel to the miter slot so I left that alone. I adjusted the T-square style fence to get the far end (away from the operator) tailed away from the blade about 0.003”. I check the faces of the fence to be sure that they were square to the table which they were. I also checked the 90 and 45-degree stops and found them to be right on the money as well. Not bad at all right out of the box.

The SawStop Brake System

|

|

The innovative blade break system lives just below (left) the blade. there are two versions of the cartridge (right) the one for regular blades in the fore ground and another for dado blades behind that. Click images to enlarge |

|

Not surprisingly, the major share of the discussion regarding the SawStop machines revolves around the brake unit. The importance of this innovation should not be underestimated. Though many SawStop owners may never actually use the brake system there are huge numbers of woodworkers investing in this peace of mind. The potential for major injuries is always present in woodworking but the SawStop system at the very least is capable of mitigating the severity of most if not all of the potential injuries.

The SawStop cartridge and supporting circuitry monitors the electrical state of the blade. Humans also have electrical properties and when our skin touches the blade, the change in the electrical state is picked up by the SawStop system brake system and it stops the blade and moves it below the table surface. I am certain that this is way easier to describe than it was to develop.

When the SawStop System detects skin touching the blade it triggers the release that sends a specially designed aluminum pawl into the blade, stopping its rotation in 3 to 5 milliseconds. When the blade comes to such a sudden stop that surge of (angular) momentum is used to drive the blade down below the table surface. That happens within 15 to 20 milliseconds. Incidentally, 3 to 5 milliseconds is about 1/200th of a second. To put 3-5 milliseconds into perspective consider that the blink of your eyes just seconds ago took 300 to 400 milliseconds, or roughly 100 times longer than the time the SawStop System needs to stop the blade, put it below the table surface and shut off power to the motor. So, if your finger touches the blade do you want to rely on your reaction to get you out of trouble or the SawStop System that does it 100 times faster than the blink of an eye?

|

|

A nice miter gauge (left) comes with the saw as do the selection of tools (right) that are needed for assembly and setup. the yellow plastic "holder" doubles as a thickness gauge for setting the SawStop brake cartridge-to-blade clearance. Click images to enlarge |

|

The SawStop System cartridge costs about $69 each for normal blades and is destroyed when it deploys. A few teeth on the blade are also typically damaged and can be repaired in some cases or thrown out. the quality (price) of the blade will dictate repair or trash. The folks at SawStop foresaw the potential for unnecessary activations and built in a By-Pass mode that lets you disable the firing part of the SawStop System while leaving the sensing circuitry working. This way you can carefully make a test cut or two in suspect wood (wet) and see if the system senses anything. The lights on the switch box tell you if the SawStop System has made a detection and would have triggered the brake stop cartridge. You have to use an included key to disarm the firing part of the SawStop System so this does not happen by accident. Also, the next time you turn the SawStop Professional Cabinet Saw on, the detection system is back operating normally until you again use the key to disarm it.

Wet wood is rumored to cause the SawStop System to fire but that is not necessarily true. If the wood is wet enough to conduct the electrical property of your body, the SawStop System might fire. We also have to keep in mind that since the government outlawed arsenic in pressure treated wood a material that is rich in copper has taken its place. The hyper conductivity of copper can make the SawStop System think that you have touched the blade if there is enough of it in the wood being cut. This copper-containing preservative and wet wood cold combine to cause problems with the sensing system as well.

We will look at the SawStop System in detail, including how to use it in a separate story. In that story we will show you exactly what it looks and sounds like when the SawStop System stops the blade. It is impressive as well as ultra-fast. This is an important safety innovation and deserves a full description.

In the Shop

|

|

The blade guard (left) is very innovative due to its hyper-effective dust control and safe design. The riving knife (right) is also supplied. changing between the blade guard system and the riving knife is very fast and tool free. Click images to enlarge |

|

From the first time I started the SawStop System it has run very quietly and smoothly. Its 3 HP motor delivers all the power any woodworker needs and does it without sag or bogging. Start up and coast down are both relatively short-term events which reduces the temptation to retrieve a cut off piece from near a still-spinning blade.

Everything about the SawStop System just works very well from the large cast iron hand wheels to the rip fence and the innovative blade guard/dust system. The locking pins on the hand wheels do their job without “tweaking” the blade height or bevel adjustments. The whole trunnion system runs smoothly and easily throughout its travel.

The single lever clamp used to change from the full guard assembly to the included riving knife is simple but well thought out and very secure. All of the controls are easy to use and predictable in function. Even the miter slots are precisely machined and very consistent in width. I worked with the included miter gauge quite a bit and it fits the t-shaped slots well maintain a bunch of accuracy for a factory gauge.

The SawStop Professional Cabinet Saw even comes with a nice SawStop carbide-tipped combination blade that performs very well in all of the situations I could think of. During the evaluation I tried all of the cuts we use in the ship, rips, crosscuts, miters and bevels. The SawStop Professional Cabinet Saw breezes through all of them. And it does all this with the innovative SawStop System waiting to take over if you make a critical mistake.

I have seen lots of forum mentions about the SawStop System firing because of wet wood and other causes. There is a Bypass Mode that is explained in the instructions that lets you test the wood but for some reason this seems to escape some of the users. I will be doing a full story on the SawStop System very soon and we will look at the common ways the cartridge fires and how to use the testing Bypass Mode. Stay tuned!

Conclusions

Video #1 |

Without minimizing the importance of the SawStop brake system I have to say that even without that feature the SawStop Professional Cabinet Saw might still be at the head of the best table saw table, at least of the ones that I have used. It is exceptionally well built and includes innovative features that we just do not see grouped on any one of the competing machines. Little things like the bracket under the edge of the extension table to bigger things like the truly innovative dust collecting blade guard add up to a table saw that is just better that its contemporaries. The SawStop Industrial Mobile Base is on its own planet somewhere easily surpassing any base I have used or have seen. This kind of dominance should spur the rest of the machine-building world to take another look at their “affordable” bases and those frustrating wheel locks.

Of course, the SawStop Professional Cabinet Saw is not free but all things considered carries a much lower price tag than I anticipated. The SawStop Professional Cabinet Saw with 36” fence (as reviewed here) has a street price of $2899.00, (3-17-2012) the SawStop Industrial Mobile Base is selling for about $299.00 on the street with the regular blade brake cartridges costing $69.00 and the special dado brake cartridge $89.00. I know it is a wad of money but if quality and maximum safety are important to you, the price of admission is surprisingly low. If the SawStop Professional Cabinet Saw ever saves you one blade contact injury it very well may have just saved you more money than this whole outfit costs – and then some.

See Part 2 of the SawStop Review - Click Here

Visit the SawStop web site – Click Here

Have a comment on this review? –Email Me!

All written, photographic and drawn materials are property of and copyright by NewWoodworker.com LLC 2000-2019. Materials may not be used in any way without the written permission of the owner.