This is a Veteran Owned site

Wobble Dado Blades

Wobble Dado Blades

|

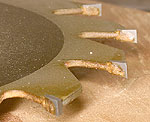

Using a wobble dado is a good way to save a few bucks and then mess up everything you do with it after that. Click image to enlarge |

A last resort - maybe

Text & Photos by Tom Hintz

Update: Recently I received an email from a fellow who is successful in using a wobble dado blade. While all other contacts (hundreds of them) have been negative, this one shows that this style of blade can in fact meet expectations. As always, consider all options, and then choose the one that seems best for you.

I receive a slow but steady stream of emails asking about wobble-style dado blades. While the majority of the senders are relatively new to woodworking, some have more experience and seem to be looking for someone to reinforce the doubts they already have about the wobble dado. In either case, the answer remains the same - stay way from wobble dados unless they are the only alternative.

The Concept

|

This split hub, common on virtually all wobble dados, can allow small but important radial deviation of the whole assembly and cause significant vibrations. Click image to enlarge |

Wobble dado blades are a low-cost compromise to the more expensive but vastly more effective stacked dado sets. The wobble dado uses a single blade, mounted on a multi-piece hub that can be adjusted to vary the angle at which that blade is to the arbor shaft. This angle regulates with width of the dado cut. Unfortunately, that wobble causes as many problems as it solves, maybe more.

Vibration

Intentionally spinning a blade at an angle that grows steeper as the width of cut is increased is a sure way to cause a vibration. Combined a multi-piece hub assembly that can permit small but important radial irregularities, this arrangement can give the best saw a serious case of the shakes. These vibrations are made worse when the wobble dado is used the relatively light benchtop and entry-level tables saws.

In addition, as the cut width is increased, the teeth of the wobbling blade tend to impact the sides of the groove, causing more vibration.

Cut Quality

|

The dado on the left was done with a Freud stacked set. On the right is one (same size) done with a wobble dado, on the same saw, on the same day. Click image to enlarge |

Another problem with running the blade at an angle is that it does not pass through the groove it is cutting cleanly. This problem is made worse if the saw is not perfectly aligned as is often the case with any tables saw but more so on the benchtop or entry level machines that have less sophisticated fence and blade support mechanisms.

The whole premise of a wobble blade makes it impossible to the use of advanced, multiple tooth designs that make a good stacked dado set so effective and clean cutting.

The result is often severe chipping or tearout, especially in veneer plywood. This irregular contact with the wood, combined with "economy", uncoated blade bodies often found on wobble dados seems to generate contamination of the blade very quickly.

In addition, turning an angled blade means the teeth swing through an arc as it rotates. That makes it physically impossible for it to cut a flat-bottomed dado, instead cutting a concave bottom surface. In addition, the depth of that concave shape increases with the width setting.

What Can You Do?

Frequently, wobble-style dado blades are considered because of a short arbor that will not safely handle a stacked dado blade set at its full width. That is a very real safety concern because the arbor nut must be fully seated on the shaft with at least one full thread protruding above it's surface when tightened.

Despite the short arbor, most saws are capable of using a stacked dado set if the number off chippers installed between the outer plates is limited. Some instruction manuals provide a specification regarding dado blade width and diameter. If it does not, contacting the saw manufacturer is the only sure way to get credible information on this capacity.

Stacked dado sets are available in 6" and 8"-diameters but in most cases the 6" set fits benchtop and entry-level saws best. The smaller diameter is also lighter which can be important with saws under 1 ½ Hp. The vast majority of dado are in the ¼" to ¾" depth range which is easily handled by the 6"-diameter stacked sets.

|

In my opinion, the wobble dado and its angle-producing split hub, should be avoided. There are much better, more effective choices. Click image to enlarge |

Conclusions

My best advice is to avoid wobble dados whenever possible. There may be a saw out there that cannot use a stacked set at all, but I have not heard of it yet. In all cases I am aware of, if the saw will swing a wobble dado, it will run a stacked setup in a reduced width configuration.

Stacked dado sets generally cost more than the wobble variety but there is good reason for that. I also think that if you compare the price of a good 6" stacked dado set to the cost of a wobble type, you will find that difference is not as significant as you might suspect. For example, Freud offers a very capable 6"-diameter stacked set with a street price ranging from $19.95 to over $50.00 (5-10-2004).

Like many of us, you might have to save up for the better stacked set and you will probably have to make two or more passes to cut some dado widths. However, the quality of the dados themselves combined with the longer life of the stacked set will make the delay worthwhile.

Do you have a comment about this story? - Email Me Here

All written, photographic and drawn materials are property of and copyright by NewWoodworker.com LLC 2000-2019. Materials may not be used in any way without the written permission of the owner.