This is a Veteran Owned site

|

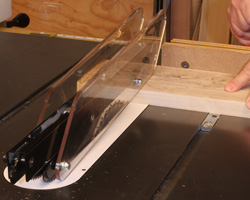

Learning to set up and use the factory safety equipment is a sure step in the right direction towards preventing injury. Click image to enlarge |

Safety Survey 2 Report

Once again, cause for concern

Text, survey and photos by Tom Hintz

Posted - December 2002

Several years ago I did the first NewWoodworker.com Safety Survey and it got lots of response from the woodworking community. With nearly 300 legitimate responses, the results of the original Safety Survey surprised me a bunch. Not so surprising because of the format was that nearly all of the respondents admitted suffering some form of injury in woodworking. What shocked me was that virtually all of them took full responsibility for the accident. Very often they had been doing whatever it was for some time and getting away with it. Then, their luck ran out and they were injured. This survey echoed some of those same points.

In Safety Survey 2 I wanted to get a somewhat more detailed look at woodworking related injuries to help define the future editorial plan for NewWoodworker.com. This time I had software with far more capabilities including the ability to present the results on my site in real time so everyone could see it develop. Naturally there were a few that did not like the survey design or thought this whole effort was simply a ploy to swipe some kind of information from them. Within any large segment of humanity there will always be a small group that share a tenuous grip on reality.

Though Safety Survey 2 will continue to run on NewWoodworker.com indefinitely, at this writing we had just over 600 responses! That means that our data set is roughly double that of the first Safety Survey. Despite the few who tried to skew the results the trends were surprisingly well defined by the time 200 people had taken the survey. As the number of respondents grew, those trend percentages remained virtually unchanged as the numbers surpassed 600 respondents.

Controversy

|

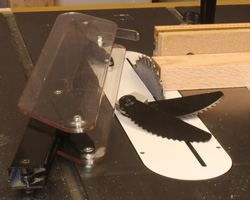

Too many woodworkers are removing the factory safety equipment and paying the price for that action. Click image to enlarge |

Soon after posting the Safety Survey 2 some folks took exception with how it was designed because it probably would not generate the information they thought it should. No survey is going to be perfect no matter how it is laid out or how big it is. I am not a professional pollster but have seen how other surveys/polls I have run worked and used that experience to put the Safety Survey 2 together.

The most controversial question regarded household income. Some could not see any relevance at all while others thought it was an attempt to get personal financial information even though the survey had no way to tie any income entry with any respondent. My purpose here was to see if there were more woodworkers in a specific income level. A high percentage of respondents in a specific income group could show a need to focus a little more on specific tool/machine/project price points. However, Safety Survey 2 showed virtually no dominant income level. While the biggest age group was 66 to 70 years (21.9%) income levels were very evenly dispersed. The $40,000 to $50,000 group was the largest but it drew only 14.38% of the overall responses. The majority of the remaining income levels drew between 7% and 10% of the responses. None of the levels have a big enough disparity to set them apart significantly. Woodworking truly appears to be an "everyman's hobby.

Veteran or Not-So-Veteran

Experience levels in woodworking were also surprisingly evenly divided. Though 28 to 30 years drew the most responses (18.90%) 0 to 3 years and 4 to 7 years each drew 16.72% of the responders. 31 years and up got an unexpected 14.38% response which indicates that lots of us live long lives and don't give woodworking up easily!

One of the more definitive data points was the Hobbyist vs. Professional woodworker bracket. A whopping 90.97% deemed themselves to be in the Hobbyist group leaving only 9.03% of the total respondents calling themselves professional. Somewhat surprising was the ratio of shared workshop spaces (54.68%) to dedicated (45.32%) shops. I would have put real money on shared spaces coming in at around 70% but not so.

Woodworking habits, how often you get in the shop were also pretty clear. 31.10% does woodworking every day while 53.34% get to the shop once or twice per week. Less involved at once or twice per month came in at 14.05% and those who "Rarely" do woodworking showed a meager 1.51%. Clearly those involved in woodworking enjoy it!

The Down Side

|

Thankfully the severity of most injuries was minor and the costs reflect that. However, these injuries also suggest being VERY close to disaster. Click image to enlarge |

Here is where the numbers turn somber. Though I fully expected a sizeable portion of the sampling to report injuries, the size of the disparity is concerning. From the earliest numbers right at 80% (79.77%) reported having had some kind of injury in the shop compared to a surprisingly small (20.33%) that had remained injury free. As the number of respondents grew, those percentages held steady. To be sure the range of injury severity is skewed heavily towards the minor but this is still way too many injuries minor or not.

Of the injuries reported cuts (79.77%) and bruises (17.73%) remained at the top of the list throughout the growth of the survey. Those percentages were not all that surprising, just as with seeing sprains (0.84%), dislocations (0.33%) and broken bones (2.17%) representing the less frequent injury types. What was very surprising was having amputations (many of those reported as losing portions of fingers, fingertips etc.) coming in with 3.01%! Even after having corrected this number for the expected number of false reports (it was higher) made by the mental midgets wanting to skew the survey, that is WAY too many to me.

The good news is that because the vast majority of injuries were minor the largest segment (72.58%) reported overall costs of their injuries in the $0 to $500 dollar range. In view of today's medical costs, that is as close to nothing as we are going to get. The next cost range of $501 to $1000 was also the next highest (14.38%) in numbers, which further suggests a low severity level overall. However, the next highest number (2.34%) reported injury costs of $10,000 or higher. The raw numbers here coincide closely with the number of amputation type injuries so these two numbers would seem to verify each other.

The Machines

The fact that the table saw (42.98%) lead all machines with the number of injuries reported was no surprise. Virtually everyone has a table saw and nearly that many use it far more than other machines and tools. What was interesting was the remaining spread of injuries in the powered tool categories. The miter saw (3.68%) was expected to be higher in the mix but finding the router table (6.86%) in second place got my attention. The jointer (3.01%) was next followed by the hand-held drill driver (2.34%) and the bandsaw (2.17%).

"Other hand tools" the non-specific un-powered group which covers things like chisels, knives and such drew a surprising 10.37%. In the first Safety Survey hand tools went virtually unmentioned and I am not sure why as that survey had far more "write in" categories. Also, the vast majority (71.40%) of respondents said that the tool in question was not new to them.

How it Happened

|

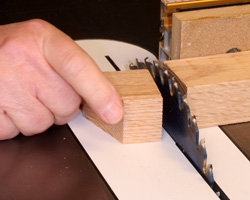

Way too many woodworkers can't seem to wait for the blade or cutter to stop before reaching in for a cutoff piece. Click image to enlarge |

The leading reported cause for injury (39.46%) was contact with a spinning blade or cutter. Kickback (17.89%) was next with 16.39% reporting "other" injury situations. Various other common situations like broken wood and such came in with about 3% or less.

The machines in question had their factory-supplied safety equipment in place only 32.44% of the time. A too-large portion (44.98%) of the respondents had removed that equipment prior to the accident occurring. 63.55% were not using a push stick, push pad or push handle (only 12% were using one!) and only 6.35% reported being distracted by something in the shop at the time of the accident.

68.23% felt that their own complacency contributed to their injury. Add to this that only 4.18% thought that the machine being used had a deficiency that contributed to the accident. 71.91% reported having done the injury-producing procedure in the past without incident.

Fully 75.25% blamed themselves for the accident. This is nearly identical to the percentage who blamed their accidents on themselves in the first Safety Survey. While 70.40% report having altered how they performed the injury-producing procedure after the accident, only 33.11% had added safety equipment following the injury and only 21.57% reported re-installing the factory safety equipment after the accident. Those numbers strongly suggest that too many woodworkers have a tough time learning from their accidents.

Conclusions

While the severity of woodworking injuries are minor and the related expenses comparatively small there are simply too many of them in my estimation. The thing that bothers me about the majority of these injuries is how easily the minor ones could become major ones. No matter how minor the injury is from touching a spinning blade or cutter, you are right on the verge of a devastating incident.

|

Taking the time to use a decent push handle could easily save a bunch of recovery and expense. why is it that so many refuse to use this simple (and cheap) piece of safety equipment? Click image to enlarge |

The purpose of the Safety Survey 2 was to find areas that I could address with future articles. In that regard this effort has been very successful. I have already completed the first story generated by the Safety Survey 2 and comments added by respondents "Setting Up Factory Blade Guard Systems" but many more will follow in coming months. I have several more stories already on the list but welcome article content suggestions from NewWoodworker.com viewers and manufacturers.

I have no delusions of being able to eliminate injuries from the woodworking shop but I think we can help some of our viewers work safer. Safety has always been a core goal on NewWoodworker.com but the results of Safety Survey 2 suggest that more editorials are needed and I will revise my editorial plans accordingly. I try to incorporate safety information in every applicable story but I will expand the content aimed specifically at safety issues in the future.

In the mean time, all of you need to take a moment to look at how you work in your own shops. Woodworking is a hobby for the vast majority of us and we should not be taking unnecessary chances that could impact our ability to generate the income that supports our hobby. Have fun but take the time to be safe!

Haven't taken the Safety Survey 2 yet? - Click Here

Have a comment on this story? - Email Me!

Back to the Articles Directory

All written, photographic and drawn materials are property of and copyright by NewWoodworker.com LLC 2000-2019. Materials may not be used in any way without the written permission of the owner.